In manufacturing, the warehouse is the critical link between planning and production. Inefficient processes here trigger immediate problems: line stoppages, material shortages, and rising costs. Many manufacturers in Thailand use ERP for planning, but ERP is not built for real-time warehouse control. Picking, issuing, and put-away remain manual, creating dangerous gaps that grow riskier as production scales. That’s where a Warehouse Management System (WMS) steps in. By digitizing operations and enforcing discipline, WMS delivers accurate inventory, stable production uptime, and real cost savings for Thai plants.

What is a Warehouse Management System?

Definition of a Warehouse Management System

A warehouse management system (WMS) is a software system designed to manage and control warehouse operations at the execution level. In manufacturing environments, a WMS governs how materials are physically received, stored, moved, picked, and issued inside the factory.

Unlike ERP systems, which focus on transactional data and planning logic, a WMS warehouse management system operates in real time. It controls warehouse activities based on actual material movement, location data, and operational rules. This allows manufacturers to maintain accurate inventory records while ensuring materials are available when production needs them.

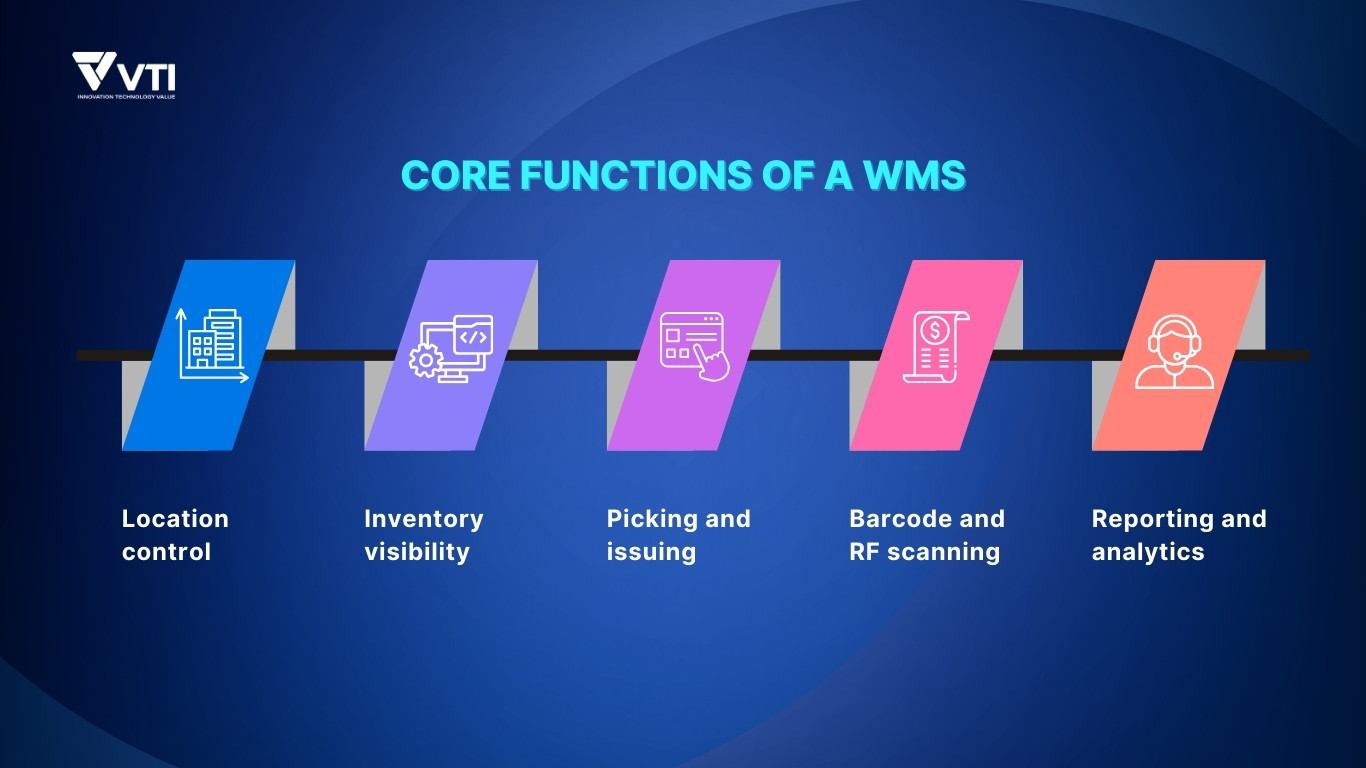

Core Functions of a WMS

Modern WMS systems provide several essential capabilities that form the foundation of effective warehouse control.

- Location Control: Every item stored in the warehouse is assigned to a specific physical location. This creates a precise digital map of inventory placement, enabling accurate tracking and efficient retrieval.

- Inventory Visibility: Real-time visibility into what materials are available, where they’re located, their quantities, and their status whether available, reserved, or quarantined.

- Picking and Issuing: Systematic guidance for warehouse operators on which materials to pick, from which locations, and in what sequence to fulfill production requirements efficiently.

- Barcode and RF Scanning: Integration with handheld devices and barcode scanning technology ensures accurate data capture at every transaction point, eliminating manual entry errors.

- Reporting and Analytics: Comprehensive reporting on warehouse performance, inventory levels, transaction history, and operational efficiency metrics.

In practice, these functions remove dependency on individual experience and make warehouse execution predictable, repeatable, and auditable.

How WMS Enables Advanced Warehouse Technologies

Once core warehouse execution is standardized, a WMS naturally becomes the coordination layer for advanced warehouse technologies.

In large manufacturing warehouses, drones are increasingly used to support cycle counting and location verification. When connected to the WMS, drones can scan barcodes or RFID tags on high racks without interrupting daily operations. This helps plants maintain inventory accuracy while reducing manual labor and safety risks.

Modern WMS platforms also integrate with automation and material handling systems such as conveyors, AS/RS, AGV, and AMR. Rather than moving goods randomly, the WMS makes execution decisions—what to move, when to move it, and where it should go—based on real production demand and inventory rules.

By combining execution logic with automation, manufacturers can shorten material travel time, balance warehouse workloads, and keep material flow synchronized with production lines.

Who Typically Uses a Warehouse Management System?

Warehouse management systems are used across a wide range of industries where inventory accuracy, speed, and control are critical.

- In distribution and logistics environments, WMS is primarily used to manage high-volume inbound and outbound flows, optimize picking routes, and ensure fast order fulfillment for customers.

- In retail and FMCG operations, WMS helps manage large SKU volumes, seasonal demand fluctuations, and store replenishment accuracy.

- In regulated industries such as pharmaceuticals, chemicals, and food processing, WMS plays a critical role in enforcing FIFO/FEFO rules, managing batch traceability, and supporting audit compliance.

Among all these use cases, manufacturing environments place the highest execution demands on a warehouse management system.

Unlike distribution centers, manufacturing warehouses directly affect production continuity. Any breakdown in warehouse execution can immediately impact output, quality, and delivery reliability. For this reason, the remainder of this article focuses specifically on how warehouse management systems are applied in manufacturing plants in Thailand.

Why Warehouse Management Is Critical in Manufacturing Environments

Warehouse vs. Distribution Center

A common misconception is treating manufacturing warehouses the same as distribution centers. While both store inventory, their operational priorities differ fundamentally.

Distribution centers focus on throughput—moving finished goods from suppliers to customers as quickly as possible. Manufacturing warehouses, however, are tightly integrated with production operations. They serve as the critical buffer between material availability and production line requirements.

In manufacturing, the warehouse is directly connected to production line feeding, work-in-process staging areas, quality control and compliance requirements, and production scheduling constraints. The warehouse doesn’t just store materials—it enables production execution. When warehouse operations falter, production lines stop, quality issues emerge, and delivery commitments fail.

How warehouse issues undermine manufacturing output

When warehouse execution is not properly controlled, manufacturing plants often experience:

- Production line stoppages due to missing materials

- Wrong material issuance leading to quality issues

- Manual FIFO execution increasing compliance risk

- Heavy reliance on operator experience

These issues directly affect output, delivery performance, and operating cost. In many cases, the root cause is the absence of a structured management warehouse system capable of enforcing standardized execution.

Common Warehouse Challenges in Thai Manufacturing Plants

In manufacturing plants across Thailand, warehouse challenges are daily issues that directly affect production performance, delivery reliability, and cost control.

One of the most common pain points is inventory inaccuracy. Many factories still rely on periodic stock counts or spreadsheet-based tracking. This leads to discrepancies between system records and physical inventory, forcing production planners to build safety stock buffers to avoid line stoppages. While this approach reduces immediate risk, it increases inventory carrying costs and ties up working capital.

Another major challenge is poor FIFO and FEFO execution. In industries such as food, chemicals, electronics, and automotive, materials must be consumed in the correct order to maintain quality and compliance. Without system-enforced rules, warehouse staff often rely on experience or convenience when issuing materials. This increases the risk of expired materials, obsolete stock, and audit findings.

Manual picking and issuing also contribute to operational inefficiency. In many plants, warehouse operators decide which materials to pick and which routes to follow based on habit. This results in longer travel distances, inconsistent picking times, and higher error rates. Over time, these inefficiencies accumulate into measurable productivity losses.

A further issue is the lack of real-time visibility. Without accurate, up-to-date inventory information, plant managers cannot quickly respond to production changes or disruptions. Decisions are often made based on outdated data, increasing the risk of material shortages or overproduction.

Studies on warehouse and logistics operations in Thailand have shown that weak inventory control and unstructured warehouse execution are key contributors to high operating costs and delivery delays. In manufacturing environments, these problems are amplified because warehouse issues immediately affect production lines.

Without a warehouse management system to enforce standardized processes and provide real-time visibility, these pain points continue to limit operational performance and scalability.

How a Warehouse Management System Solves These Challenges

A modern warehouse management system addresses manufacturing warehouse challenges by transforming manual, experience-based work into standardized, system-driven execution.

The first major improvement is inventory accuracy and visibility. With barcode or RF scanning, inventory data is updated in real time whenever materials are received, moved, or issued. This eliminates reliance on periodic stock checks and provides production planners with accurate, current information about material availability and location.

A WMS also enforces FIFO and FEFO rules automatically. When materials are received, the system assigns them to specific locations and records lot, batch, and aging data. During picking and issuing, the system selects materials based on predefined rules rather than operator judgment. This reduces waste, improves quality compliance, and supports audit readiness.

Another key benefit is task-based warehouse execution. In a WMS system warehouse, tasks such as put-away, picking, replenishment, and cycle counting are assigned by the system based on priority and location. Operators follow optimized task sequences, reducing unnecessary movement and improving productivity. This structured approach is especially valuable in plants with high workforce turnover or multiple shifts.

A warehouse management system also supports performance measurement and continuous improvement. By capturing detailed operational data, the system enables plant managers to monitor KPIs such as inventory accuracy, picking error rates, and material availability at line-side. This data provides a factual basis for identifying bottlenecks and improving processes over time.

In manufacturing environments where production stability is critical, a WMS serves as the execution backbone that aligns warehouse operations with production needs. This shift allows manufacturers to control material flow proactively, instead of firefighting issues after production has already been disrupted.

How WMS Works with ERP and MES in a Manufacturing Plant

Role of ERP, WMS, and MES

In a typical manufacturing IT landscape:

- ERP manages planning, purchasing, and production orders

- WMS executes warehouse operations

- MES manages production execution and material consumption

The warehouse management system (WMS) acts as the execution layer that connects planning with production reality.

End-to-End Material Flow

A common end-to-end material flow includes:

- ERP generates a production order

- WMS allocates materials based on location and FIFO rules

- Materials are issued and delivered to the production line

- MES confirms material consumption

- Inventory data is synchronized back to ERP

This closed-loop process ensures data consistency and operational accuracy across systems.

Why WMS Is Critical in This Flow

ERP systems are not designed to manage detailed warehouse locations or real-time execution, while MES focuses on production rather than warehouse tasks. This integration model is widely adopted in manufacturing WMS systems in Thailand to ensure smooth material flow and production continuity.

Key Warehouse KPIs That Matter to Plant Managers

In well-implemented WMS projects, many manufacturing plants report measurable improvements across these areas:

| KPI | Before WMS | After WMS | Impact |

| Inventory Accuracy | 92-95% | 99%+ | Reliable planning, reduced safety stock |

| Line-Side Material Availability | 85-90% | 98%+ | Fewer production disruptions |

| Dock-to-Line Time | 24-48 hours | 4-8 hours | Faster material velocity |

| Picking Error Rate | 2-5% | <0.5% | Better quality, less rework |

| Material-Related Production Delays | 5-10 incidents/month | <1 incident/month | Higher production efficiency |

Note: Actual results may vary depending on process maturity, system scope, and change management effectiveness.

These KPIs illustrate when properly implemented, a warehouse management system can significantly strengthen production performance and operational stability in manufacturing environments.

ROI of Implementing a Warehouse Management System in Manufacturing

When evaluated through operational performance, the return on investment becomes clear.

Accurate, real-time inventory visibility allows manufacturers to reduce safety stock and free up working capital. Improved material availability at the production line reduces unplanned downtime and increases effective production capacity without additional shifts or labor.

Automated FIFO, traceability, and audit trails reduce waste, rework, and compliance risk. In regulated industries, this translates into fewer audit findings and lower corrective action costs.

Task-based execution improves labor productivity, enabling warehouse teams to handle higher volumes with the same workforce. Combined, these benefits often allow manufacturers in Thailand to recover WMS implementation costs within two to three years.

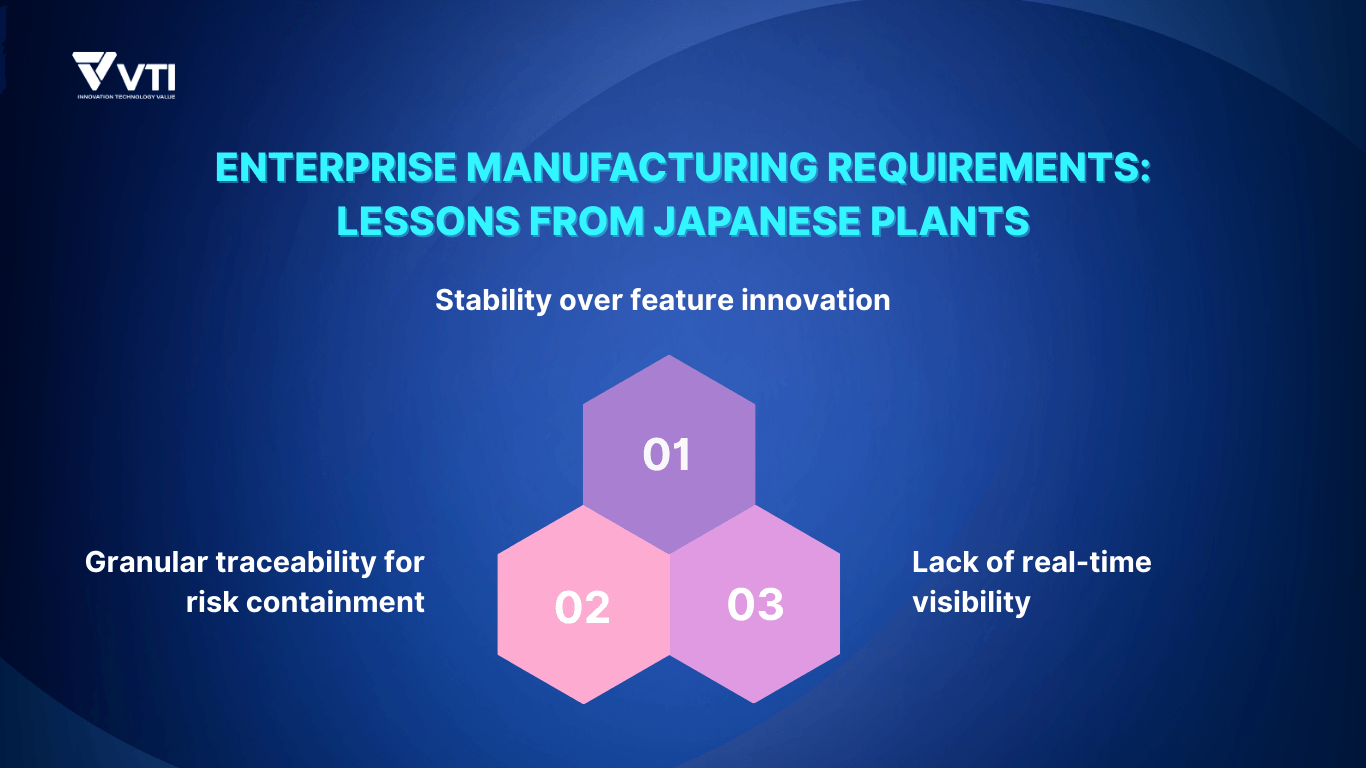

Enterprise Manufacturing Requirements: Lessons from Japanese Plants

Manufacturers with strong headquarters governance and strict operational standards often place higher demands on warehouse execution systems. Japanese manufacturing companies operating in Thailand are widely recognized as a benchmark for these enterprise-level requirements.

Rather than treating WMS as a supporting IT tool, these organizations use it as a mechanism to enforce standard work, manage risk, and ensure long-term operational stability across global operations.

Standardization as an Operational Foundation

In large enterprise manufacturing networks, standardized processes are critical for scalability and control. Many Japanese manufacturers deploy global operating templates that define how warehouse activities must be executed across all plants.

When managers rotate between factories in different countries, standardized WMS-driven processes allow them to understand warehouse operations immediately without relearning local practices. In this context, the WMS acts as an enforcer of standard work rather than a flexible workflow engine.

Systems that rely heavily on customization often struggle in such environments. Enterprise manufacturers typically prefer configurable standard processes that remain consistent across plants while allowing limited parameter-based adjustments.

Granular Traceability for Risk Containment

In industries such as automotive and electronics, traceability is not just a compliance requirement—it is a risk management strategy.

Leading manufacturing organizations operate at granular traceability levels, capturing detailed records for every material movement: lot, serial number, location history, timestamp, and operator identification. This level of visibility enables precise containment when quality issues occur, limiting recalls to affected materials rather than entire production batches.

Warehouse management systems serving these environments must support end-to-end traceability across receiving, storage, picking, and production issuing. Basic batch tracking alone is insufficient.

Stability Over Feature Innovation

For enterprise manufacturing plants, system stability consistently outweighs feature novelty. Even short periods of system downtime can result in significant production losses.

As a result, manufacturers often prioritize proven architectures, predictable performance under peak loads, and robust operational support over rapidly evolving feature sets. Stress testing under real operational conditions—high transaction volumes, network disruptions, and concurrent users—is commonly used to validate system reliability before deployment.

Managing Multi-Language, Multi-Plant Operations

Enterprise manufacturing operations in Thailand typically involve multinational teams, regional headquarters, and multiple production sites. Effective WMS platforms must support role-based multi-language interfaces and centralized visibility across plants.

This capability enables headquarters to monitor inventory, standardize KPIs, and coordinate material flows while allowing local teams to operate in their native languages without friction.

| Priority | Japanese Approach | Core Objective |

| Standardization | Global templates, minimal customization | Easy management, consistent training |

| Traceability | Barcode/RFID at every touchpoint | Minimize legal and quality risks |

| Stability | Proven architecture, 24/7 support | Zero downtime guarantee |

| Multi-Language | Role-based language, centralized reporting | Break language and geographic barriers |

These requirements reflect the operational mindset of Japanese manufacturing—continuous improvement, discipline in standard work, and a long-term view of operational stability.

For Japanese FDI manufacturers in Thailand, digital transformation initiatives such as WMS implementation must be assessed through this lens. The true value of a WMS lies not in its features, but in its ability to reinforce standard execution, reduce operational risk, and support scalable, long-term factory performance.

Best Practices for WMS Implementation in Thai Manufacturing Plants

Successful WMS implementation in manufacturing environments requires more than just software installation. It demands thoughtful change management and operational excellence.

Start with Process Standardization: Before implementing WMS technology, standardize warehouse processes. Document current workflows, eliminate unnecessary variations, and establish standard procedures for receiving, storage, picking, and issuing. The WMS will enforce these processes, so they must be well-designed before go-live.

Pilot Before Full Rollout: Rather than attempting a big-bang implementation across the entire warehouse, start with a pilot area or specific material types. This allows the team to learn the system, refine processes, and build confidence before expanding to full operations. Successful pilots create champions who can help drive broader adoption.

Train Operators, Not Only IT: Many implementations fail because training focuses on IT staff and system administrators while warehouse operators receive minimal preparation. Effective training must be hands-on, in their native language (Thai), and focused on their daily tasks. Operators must understand not just how to use the system, but why it matters for production success.

Measure KPIs from Day One: Define success metrics before implementation begins and start measuring immediately at go-live. This creates accountability, enables rapid problem identification, and provides objective evidence of improvement. Regular KPI reviews keep the team focused on business outcomes rather than just system functionality.

Invest in Change Management: Resistance to WMS implementation often comes from fear of technology or fear that the system will expose poor performance. Address these concerns openly, communicate the vision for improved operations, and involve warehouse staff in the implementation process. Their experience and insights are invaluable for successful deployment.

Choosing the Right Warehouse Management System for Your Plant

For manufacturing leaders, it is the choice of a digital execution layer that determines how reliably materials flow from planning to production.

A manufacturing-grade WMS must go beyond basic inventory tracking. It should support line-side replenishment, Work-In-Process (WIP) control, and real-time integration with ERP and MES platforms to maintain a single source of truth across operations. Without this execution-level alignment, even the most advanced planning systems struggle to deliver stable production outcomes.

Compliance readiness is equally critical. For BOI-registered factories in Thailand, accurate material traceability, lot and serial tracking, and automated reconciliation are essential to reduce audit risk and protect tax incentives. These capabilities must be embedded into daily warehouse execution, not handled through manual workarounds.

In practice, some WMS solutions are specifically designed for manufacturing execution environments. These systems emphasize standard work enforcement, granular traceability, and seamless integration with automation technologies and existing enterprise platforms. Multi-language support and local implementation expertise further ensure that global standards can be applied consistently while maintaining operational flexibility at the plant level.

For executives, the right WMS is not about software features. It is about control, continuity, and long-term operational confidence.

Discover a manufacturing-grade WMS built for real-time warehouse execution.

Improve inventory accuracy and keep production running without disruption.

Conclusion

In manufacturing environments, a WMS plays a role far beyond that of a typical IT system. It functions as the operational backbone that connects planning, warehouse execution, and production.

For manufacturing companies in Thailand, implementing the right warehouse management system improves inventory accuracy, reduces production disruption, and supports stable, efficient factory operations.

FAQs

- Is a WMS necessary if a factory already uses ERP?

Yes. ERP systems handle planning and transactions, but they are not designed for real-time warehouse execution. A WMS controls physical material movement and execution discipline on the shop floor. - How long does it take to see ROI from a WMS in manufacturing?

In well-implemented projects, many manufacturing plants report ROI within 24–36 months through reduced inventory, fewer production disruptions, and higher labor productivity. - Can a WMS support BOI compliance in Thailand?

Manufacturing-grade WMS solutions can automate material traceability, reconciliation, and reporting required for BOI audits, reducing compliance risk. - What is the difference between a distribution WMS and a manufacturing WMS?

Manufacturing WMS supports production-facing activities such as line-side replenishment and WIP control, while distribution WMS focuses on outbound throughput.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)