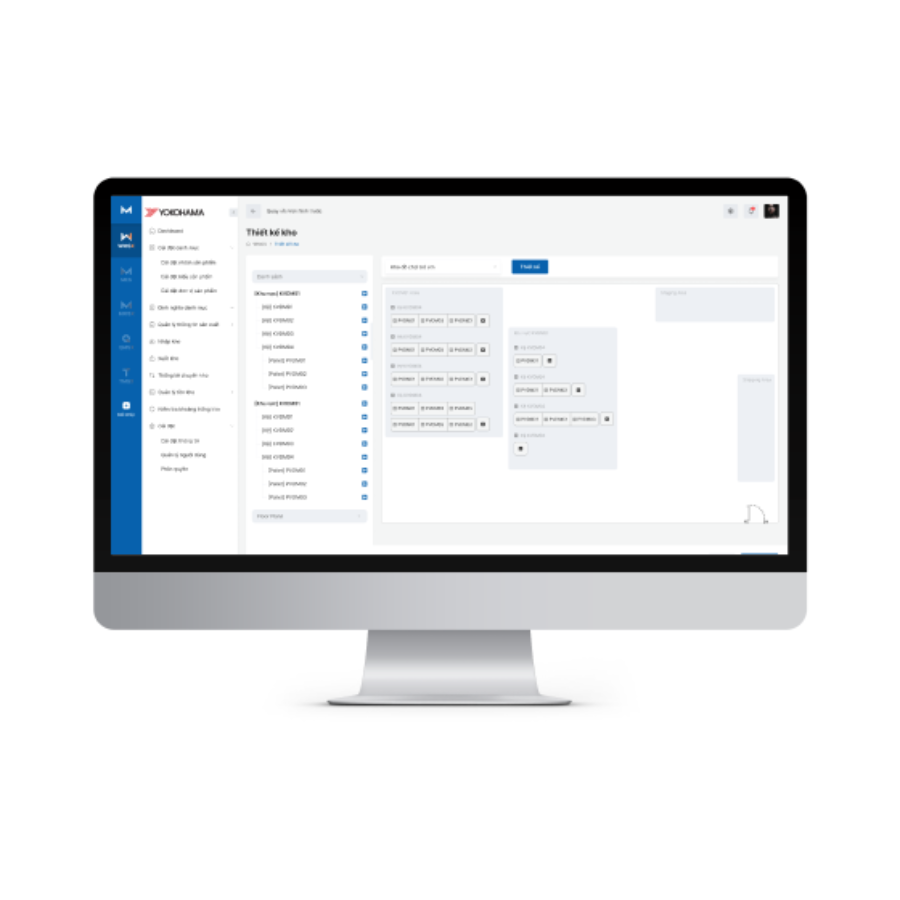

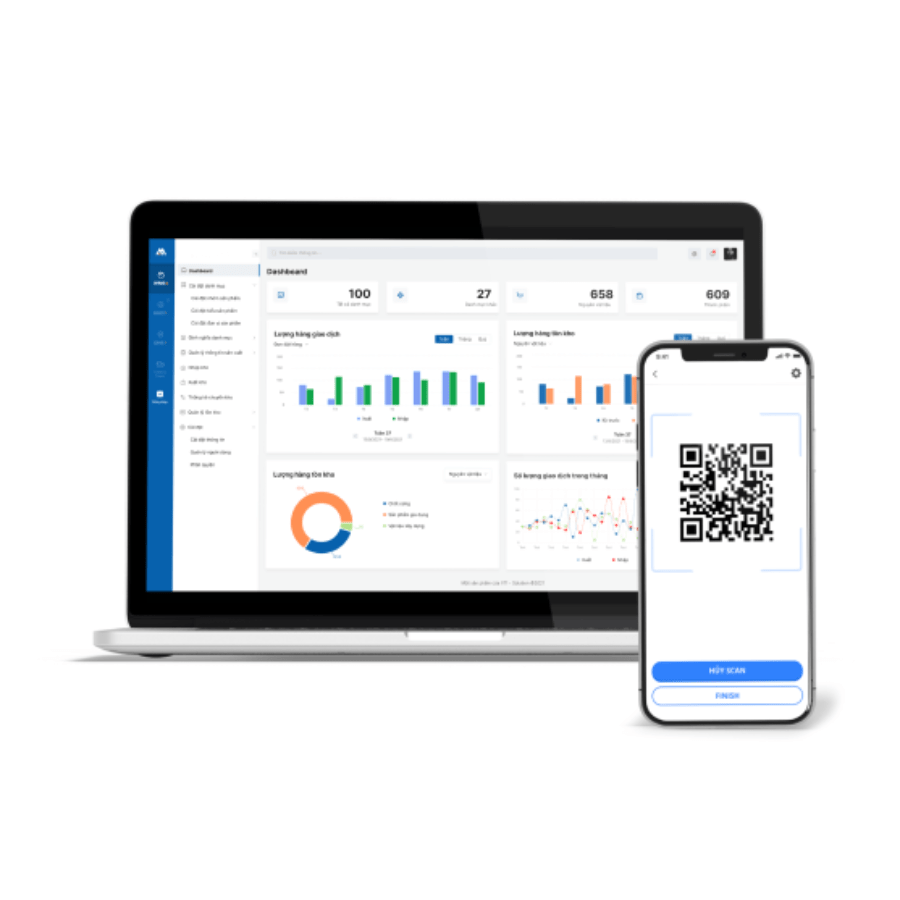

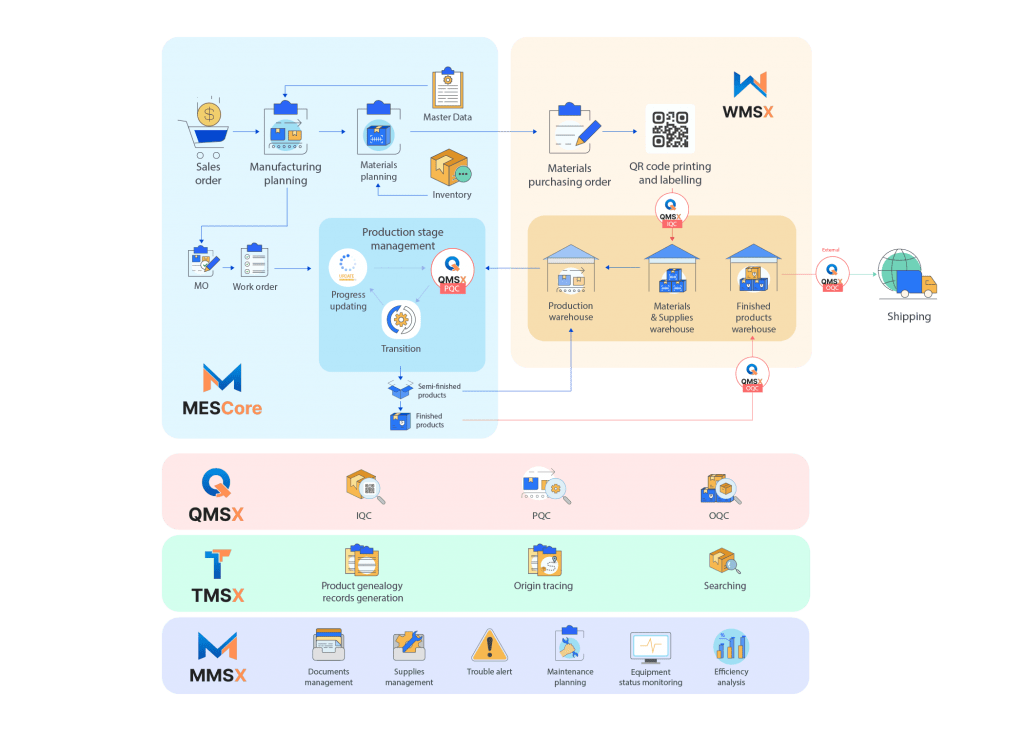

About Smart Warehouse Management System WMS-X

Smart warehouse management system with QR code:

- Automated: Automating manual warehouse operations: data collection, import/export, inventory counting, etc.

- Accurate: Accurately recording import/export information of materials, WIP, finished products, and supplies with QR code

- Just-in-time: updating manufacturing information in real-time, assisting in timely decision making

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)