Background

Our client is one of Korea’s largest chemical corporations, having established its presence in Vietnam since the early 2000s. With a strong commitment to innovation, they continuously invest in R&D to optimize production and improve product quality.

Over the past year, as part of its expansion strategy, the company sought to scale up its production lines. However, they encountered three critical challenges:

SCADA System Scalability Issues

SCADA – the central monitoring hub for all manufacturing operations, was implemented years ago by another vendor with no remaining technical documentation. This created several challenges:

- Unable to modify control interfaces for new production lines

- Difficulties in adding new control and monitoring points

- High risk when intervening with the system

Outdated MES Unable to Support SCADA Expansion

Beyond SCADA issues, their current Manufacturing Execution System (MES) was obsolete and couldn’t keep pace with connectivity and integration needs for the new SCADA. To move forward with their expansion, a modern MES is required which could seamlessly integrate with SCADA and deliver real-time data.

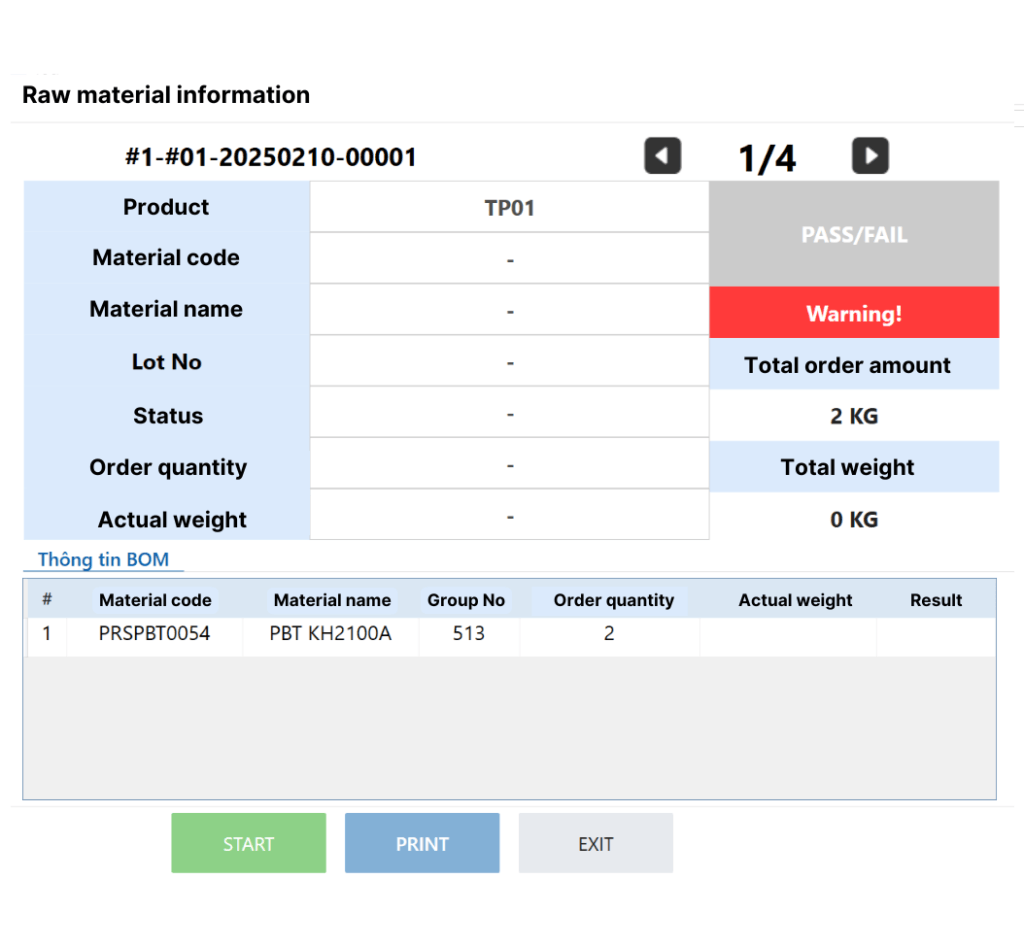

Manual Raw Material Weighing Process

As the production line expanded, the volume of raw materials increased significantly. However, the existing manual weighing process resulted in:

- Time-consuming data entry for employees.

- A high risk of human errors.

- Difficulties in synchronizing data into the system.

This inefficiency not only slowed down operations but also affected the accuracy of production data. To resolve this, the company needed an automated weighing process that could transmit data directly to SCADA and MES-X, optimizing workflow and minimizing risks.

Solution

Leveraging deep expertise in IoT and industrial automation, VTI quickly analyzed the client’s challenges and delivered an optimal solution.

SCADA and MES-X Integration

Step 1: Addressing SCADA System Challenges

Despite lacking technical documentation, the current SCADA was an open system, allowing VTI to:

- Conducted in-depth technical assessments to map system architecture and data flow.

- Identified integration points for new production lines.

- Developed scalable control interfaces and extended monitoring capabilities.

Step 2: Deploying MES-X

VTI’s MES-X was designed with high flexibility, meeting most client requirements:

- Pre-integrated production management modules.

- Customizable interfaces and reporting tools.

- Support for diverse industrial communication protocols.

- Advanced quality management and traceability features.

Additionally, VTI’s technical team tailored specific features to meet the unique demands of chemical manufacturing.

Step 3: SCADA & MES-X Synchronization

- SCADA Expansion: VTI developed new control screen interfaces for the expanded production line and programmed SCADA to connect with PLCs in the new line, enhancing monitoring and control capabilities.

- SCADA & MES-X Synchronization with an Intermediate Data Architecture: VTI built a middleware database that allowed both systems to read, write, and share real-time data, ensuring seamless synchronization and an optimized data flow.

Automating Data Collection with IoT Services

VTI implemented an IoT service capable of directly collecting data from weighing scales, transmitting it to SCADA, and synchronizing existing data tags with MES-X via a LAN network. This ensures automatic and real-time data updates, enhancing accuracy and operational efficiency.

Results

Following the implementation, VTI helped the client achieve significant improvements:

- Real-time synchronization of production data from the new line into SCADA, enabling smooth monitoring and control.

- A fully integrated MES-X system that seamlessly communicates with SCADA, ensuring fast and accurate data exchange.

- Automated raw material weighing, minimizing manual errors and enhancing operational efficiency.

Conclusion

Contact VTI today to automate and modernize your factory!

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)