In recent years, there has been a continuous increase in the demand for cold storage warehouses. According to a study by Grandview Research, the global market size for cold storage warehouses was estimated at $138.97 billion in 2022, with a projected annual average growth rate (CAGR) of 17.2% from 2023 to 2030. This growth is attributed to the heightened awareness of health issues due to the impact of the pandemic, leading to an increased demand for fresh food products. Additionally, as international trade continues to expand, there is a growing need for frozen and chilled processed foods.

Moreover, the trend towards automating cold storage warehouses is expected to further drive demand. Warehouse automation involves leveraging advanced technologies such as cloud computing, IoT, and AI to automate and optimize warehouse operations, as well as remotely manage energy consumption. Indeed, the automation of cold storage warehouses is considerably more complex than that of regular warehouses.

Warehouse Operations in a Minus 30ºC Environment

Our customer, a French company processing tropical fruits in Vietnam, faces the challenge of preserving the freshness of tropical fruits, which are prone to spoilage when exposed to hot or high-humidity weather. Therefore, a crucial element in their operations is the use of cold storage warehouses to extend the freshness of these fruits. However, the use of cold storage warehouses entails that workers must operate in harsh conditions, ranging from minus 30ºC to 35ºC. As a result, tasks such as loading and unloading require significant time and manpower. In light of this, our customer sought a solution that would allow them to manage the warehouse even in extremely cold environments.

The WMS-X System for Streamlining Warehouse Operations from Receipt to Shipment

We proposed the WMS-X system to not only accommodate special environments, such as the extremely cold conditions in the case of our customer but also to optimize the majority of warehouse operations. In the end, our customer decided to implement the WMS-X system.

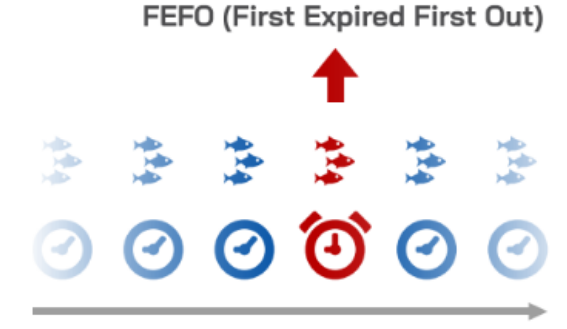

The WMS-X system is a module of our Manufacturing Execution System (MES-X) and is part of the “Made-by-VTI” suite designed to automate and optimize warehouse operations from receipt to picking and shipment. The advantages of the WMS-X system include supporting warehouse management through the utilization of FEFO (First Expired, First Out) and FIFO (First In, First Out) principles. This means prioritizing the shipment of food products based on their expiration dates.

Additionally, the WMS-X system supports picking using the fastest methods, such as wave picking, tailored to the characteristics of our customers. It also contributes to the creation of warehouse layouts, suggesting optimal placement of products in different locations, recommending free location strategies within the warehouse, and optimizing warehouse storage space.

The Benefits

Several months after the system was implemented, workers no longer had to spend extended periods in the cold arranging, picking, or packaging food. Instead, equipped with handheld terminal devices such as tablets, they can quickly locate desired food items based on the displayed layout. Furthermore, if perishable items are approaching their expiration dates, the system promptly alerts administrators. The results showed an 80% reduction in waste due to expired products.

Build a Smart Warehouse with VTI

VTI provides system development services tailored for the manufacturing industry, leveraging cutting-edge technologies and manufacturing expertise to support digital transformation and business growth in manufacturing. If you are interested in learning more about our services and solutions, please feel free to contact us.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)