Across many manufacturing plants in Thailand’s industrial estates, a familiar contrast can often be observed. Production floors run on precise schedules with efficiency tracked to the second, while warehouses rely on paper pick lists, operators searching for materials, and processes that depend entirely on who’s working the shift.

This gap does not always surface immediately, but as production complexity increases, it can become a structural risk. The warehouse is not simply a storage area—it is the execution layer that determines whether production plans are realized as intended. When material flow lacks control and visibility, even well-optimized production lines can face disruptions.

In this context, warehouse automation is increasingly viewed not as a technology upgrade, but as an operational approach to stabilize production execution, reduce dependency on individual know-how, and establish a reliable data foundation for manufacturing operations.

What Is Warehouse Automation in a Manufacturing Environment?

Warehouse automation in manufacturing refers to the systematic, system-driven control of material flow—from raw materials to work-in-progress (WIP) and finished goods—ensuring materials are available in the right quantity, at the right location, and at the right time to support uninterrupted production.

Unlike logistics-focused automation, an automated warehouse in manufacturing prioritizes production continuity, inventory integrity, and full traceability. Here, automation in warehouse operations is not about shipping speed, but about execution reliability.

Automation vs Manual and Semi-Automated Warehouses

The presence of forklifts, barcode scanners, or conveyors does not in itself constitute an automated warehouse. These elements support mechanization, not automation.

- Manual warehouses rely heavily on operator memory, paper documents, and informal practices. Process consistency varies by shift and experience level.

- Mechanized warehouses introduce equipment to assist physical handling, but decision-making remains manual. Storage locations, picking sequences, and priorities are still determined by individuals.

- Automated warehouses operate on system-defined logic. A Warehouse Management System (WMS) determines storage rules, generates tasks, sequences movements, and maintains inventory accuracy in real time. Execution does not depend on who is on shift.

In practice, automation in warehouse environments removes dependency on individual experience and ensures consistent execution regardless of workforce changes.

Why an Automated Warehouse Is Fundamentally Different

In an automated warehouse, decisions are made once—by the system—and executed the same way every time. This is the core difference between manual execution and true automation in warehouse operations.

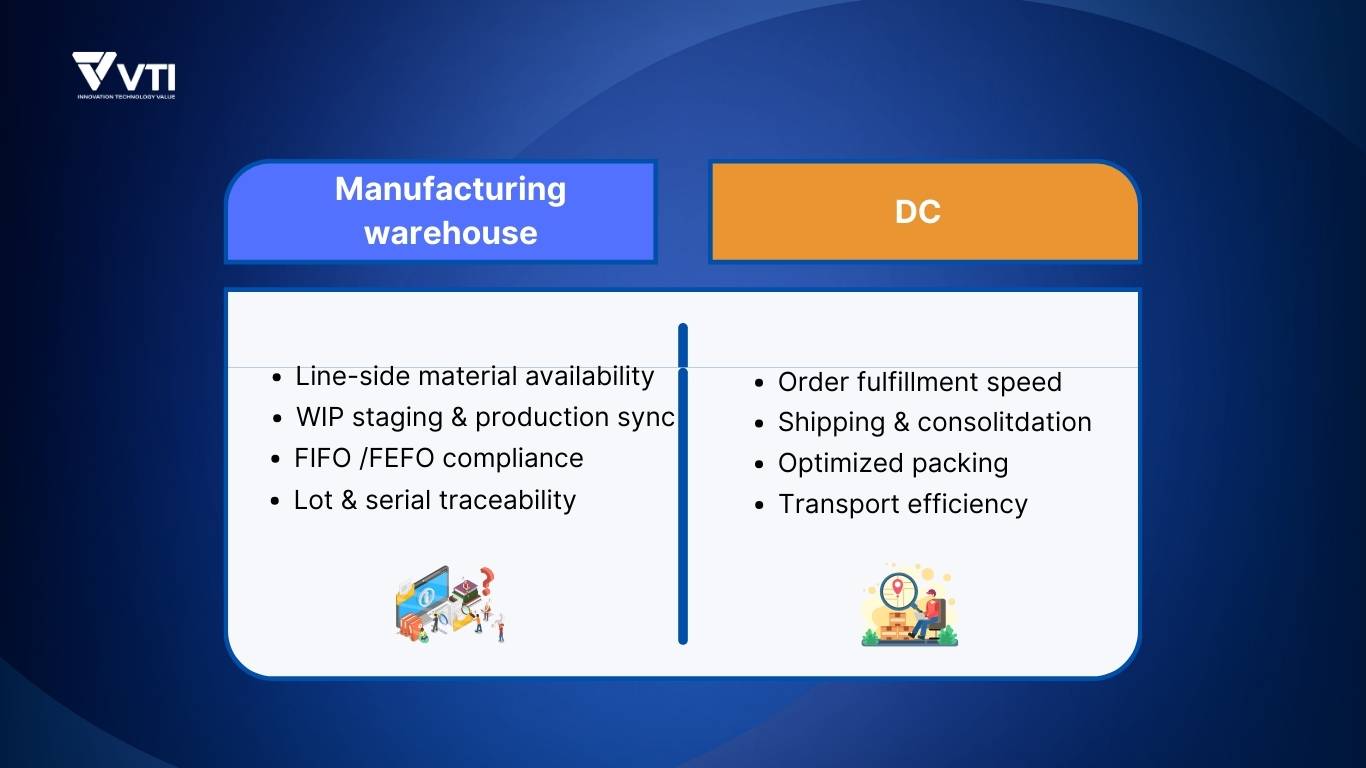

Manufacturing Warehouse vs Distribution Center Automation (DC)

Warehouse automation in manufacturing environments differs fundamentally from distribution center (DC) automation.

Manufacturing warehouses prioritize:

- Line-side material availability

- WIP staging and synchronization with production schedules

- Mandatory FIFO or FEFO enforcement

- Traceability at lot and serial level

Distribution centers, by contrast, optimize outbound speed and shipping efficiency. For just-in-time production models, even minor material delays can shut down entire lines, making automation in warehouse execution mission-critical.

Why Warehouse Automation Is Accelerating in Thai Manufacturing

The acceleration of warehouse automation in Thailand is driven primarily by operational and structural factors rather than technology trends.

Labor Instability and Skill Gap

Thailand’s manufacturing sector operates in a tight labor market. In industrial zones such as the Eastern Economic Corridor and Ayutthaya, warehouse roles often experience high annual turnover. This instability erodes process consistency, increases error rates, and makes operations dependent on undocumented individual experience.

Automation shifts operational knowledge from individuals into systems, enabling consistent execution despite workforce changes.

Global Standardization Mandates

Many Thai manufacturing plants operate as part of regional or global production networks. Headquarters increasingly require standardized processes, comparable KPIs, and transparent data across sites.

Manual warehouse operations struggle to meet these expectations. Automated, system-driven execution enables consistent material handling logic and comparable performance data across multiple plants.

Regulatory and Customer Traceability

Thailand Board of Investment (BOI) incentives, FDA requirements, and IATF 16949 automotive standards demand complete material traceability. When quality issues surface, you need immediate answers about supplier lots and affected products. Automated systems log every transaction with lot numbers and timestamps automatically.

Production Complexity

Manufacturing shifts toward high-mix, low-volume production. Plants now manufacture smaller batches of dozens of variants, each requiring unique component sets. Managing this manually becomes exponentially harder. Automation provides structure to handle complexity without chaos.

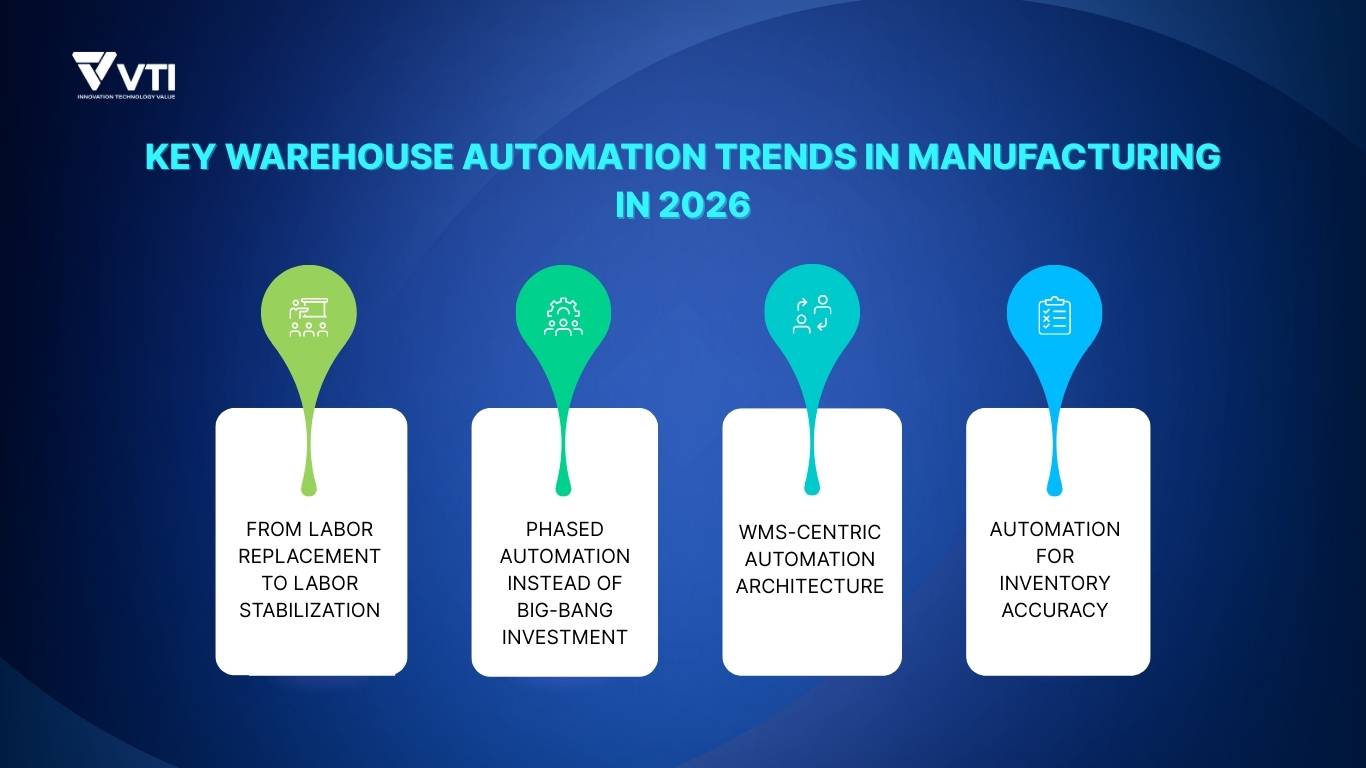

Key Warehouse Automation Trends in Manufacturing in 2026

These trends reflect shifts in operational mindset rather than specific technologies.

From Labor Replacement to Labor Stabilization

Current automation focuses on reducing dependency on specific individuals rather than wholesale headcount reduction. Automated storage doesn’t eliminate positions—it reduces time searching for materials and increases focus on exception handling and quality verification.

Phased Automation Instead of Big-Bang Investment

Plants now favor modular approaches starting with focused pilots—perhaps automating raw material storage for critical lines with ฿5-15 million investment rather than ฿50-100 million facility transformations. Initial zones prove ROI before expansion.

WMS-Centric Automation Architecture

Best practice starts with Warehouse Management Systems defining operational logic before selecting equipment. This ensures automated elements operate as coordinated ecosystems rather than independent islands.

Automation for Inventory Accuracy, Not Just Speed

In manufacturing environments, inventory accuracy often delivers more value than pure throughput. Reliable inventory enables leaner buffers, prevents line stoppages, and improves production planning reliability.

Core Technologies That Define Warehouse Automation

These technologies form the backbone of an automated manufacturing warehouse.

ASRS Warehouse Systems

Automated Storage and Retrieval Systems (ASRS) are computer-controlled installations that store and retrieve materials from defined locations with high accuracy. Common ASRS warehouse types include:

- Mini-load ASRS handle totes and bins, commonly used for electronic components and small automotive parts.

- Unit-load ASRS manages palletized materials and finished goods, frequently used in food and process manufacturing.

- Vertical Lift Modules (VLMs) utilize vertical space efficiently and are suitable for facilities with limited floor area.

ASRS warehouse is particularly effective for high-value materials, environments requiring strict FIFO control, or operations demanding near-perfect inventory accuracy.

Automated Racking and Conveyor Systems

Automated racking systems such as gravity flow racks, carton flow racks, and other dynamic storage solutions naturally enforce FIFO and improve picking consistency.

When combined with conveyors, these automated racking solutions create fixed, predictable material flows between storage, kitting, and production areas. They are often the first step plants take before fully automating warehousing operations.

AGV and AMR for Internal Material Movement

- AGVs (Automated Guided Vehicles) follow predefined paths and are well-suited for repetitive, fixed-route transport.

- AMRs (Autonomous Mobile Robots) navigate dynamically and support flexible delivery scenarios, such as line-side feeding and kitting.

Both technologies reduce manual transport effort and improve delivery consistency.

When Core Automation Makes Sense (and When It Doesn’t)

In practice, automation tends to deliver the strongest returns under the following conditions:

- Transaction volume typically exceeding 400–600 daily movements

- Product mix is relatively stable in physical characteristics

- Accuracy requirements are absolute (errors cause line stoppages)

- Labor costs often represent more than a quarter of total warehouse operating cost

- Space constraints make building expansion expensive

Conversely, automation often struggles to justify itself when:

- Processes remain unstable or frequently changing

- Product variety is extreme and unpredictable

- Throughput genuinely low (50-100 transactions daily)

- Budget constraints prevent ฿5-10 million minimum investment

A practical evaluation compares the cost of current operational issues against total automation investment and lifecycle costs.

Complementary Technologies That Enhance Warehouse Automation

Drone-Based Inventory Counting

Warehouse drones with barcode scanners conduct full facility cycle counts in 2-3 hours versus 16-20 hours manually. Best for high-bay storage or large facilities requiring frequent verification. Systems start around ฿2-4 million.

Cobots for Assisted Picking and Palletizing

Collaborative robots handle repetitive tasks like retrieving heavy items or stacking pallets while humans perform judgment-based activities. Individual cobots range ฿800,000 to ฿2.5 million.

RPA for Warehouse Administration

Robotic Process Automation handles software tasks—generating reports, updating tracking portals, reconciling documents. Typical implementations cost ฿500,000-1.5 million covering 3-5 processes.

How to Add Complementary Tech Without Over-Automating

Implement only when solving specific measured problems costing at least 3x the technology’s annual cost. Ensure WMS integration—standalone tools creating data silos defeat automation’s purpose. Start with pilots proving ROI before scaling.

WMS as the Brain of an Automated Warehouse

Why Automation Without WMS Fails

Expensive equipment sits underutilized when automation lacks a robust WMS foundation. Each system operates independently—AS/RS doesn’t communicate with AGVs, conveyors move materials without knowing production priorities. Staff create manual coordination lists eliminating automation value.

Without single-source inventory truth maintained by WMS, accuracy degrades despite automation. Manual workarounds proliferate when automated systems cannot coordinate effectively.

Event-Driven Architecture: WMS Plus Automation

Modern WMS platforms use triggered workflows where events automatically initiate coordinated actions. Production order release triggers component calculation, location identification, optimized pick sequencing, and equipment task assignment. AS/RS retrieves materials, AGVs transport to kitting areas, systems update inventory real-time—seamless flow from planning to physical execution.

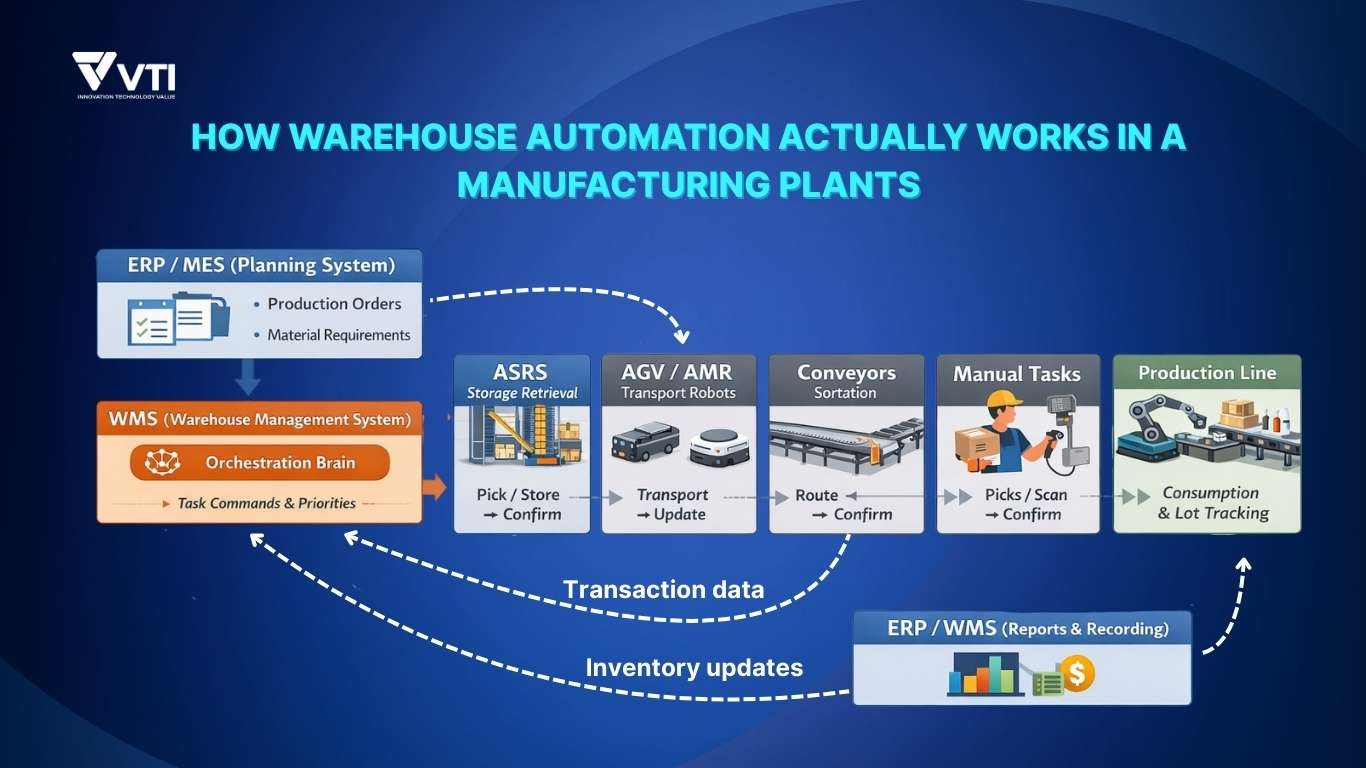

How Warehouse Automation Actually Works in a Manufacturing Plant

Warehouse automation in a manufacturing plant functions as a coordinated execution flow that connects planning systems with physical material movement. It does not replace ERP or MES, but executes their plans with speed and accuracy.

The process starts in ERP/MES, where production orders and material requirements are defined. These requirements are sent to the Warehouse Management System (WMS), which acts as the control brain. The WMS calculates exact quantities, checks real-time inventory, enforces FIFO or lot rules, and generates optimized picking, transport, and kitting tasks.

The automation layer—including ASRS, AGV/AMR, conveyors, and guided manual tasks—executes these instructions and sends confirmations back to the WMS in real time.

Once materials reach the production line, consumption and traceability are recorded, and inventory updates flow back to WMS and ERP, keeping planning and execution fully synchronized.

Best Practices for Integrating WMS with Automation Systems

Process-first design: Map and optimize material flows before technology selection. Automating broken processes creates expensive dysfunction.

Master data discipline: Automation requires pristine data. Every SKU needs accurate dimensions, weights, and storage classifications. One incorrect measurement causes repeated equipment failures.

Focused pilot zones: Start with bounded areas having clear objectives—perhaps high-value component storage for critical lines. Prove concepts, train staff, measure results before expansion.

Key KPIs for Measuring Warehouse Automation Performance

Rather than treating KPIs as fixed targets, leading manufacturers frame warehouse KPIs using benchmark ranges informed by industry references, historical plant performance, and post-automation operating data. The intent is to evaluate execution health, not to enforce rigid numerical commitments. Here are some common KPIs:

- Inventory Record Accuracy: Target >99.5% matching physical counts. Foundation of planning trust and lean inventory practices.

- Production Line Stoppages Due to Material Shortage: Ultimate effectiveness measure. Target zero. Single 4-hour stoppage at ฿2 million/hour lines costs ฿8 million.

- On-Time Delivery to Production Line: Target >98% within required time windows. Measures warehouse’s production scheduling support capability.

- Perfect Order Rate: Target >99% deliveries with correct items, quantities, lots, and no damage. Errors create immediate production impact.

- Automation System Utilization: Track productive time percentages. AS/RS 60-75%, AGVs 50-65%. Low utilization indicates overcapacity, excessive utilization indicates inadequate capacity.

ROI and Risk Considerations in Warehouse Automation Projects

Where ROI Really Comes From

Direct labor reduction is a measurable outcome in many projects. However, for manufacturing executives, the more strategic benefit lies in stabilizing operations and reallocating labor to higher-value activities rather than pure headcount cuts.

Preventing production downtime: Two prevented 4-hour stoppages annually at ฿2 million/hour lines justify ฿20-30 million investment.

Reducing inventory carrying costs: 15% reduction on ฿100 million inventory saves ฿3 million annually at 20% cost of capital.

Avoiding quality failures: Perfect traceability prevents costly recalls. Single automotive recall costs tens of millions.

Unlocking latent capacity: Supporting 20% higher production with existing footprint enables revenue growth without proportional cost increases.

Well-designed projects typically achieve ROI within 18-36 months.

Common Automation Failures

Automating chaos: Implementing automation before process standardization just systematizes dysfunction faster. Standardize manually first.

Over-customization: Highly customized solutions cannot adapt when business changes. Favor modular standard approaches.

Ignoring change management: Technology succeeds based on user adoption. Involve operators early, explain drivers clearly, allocate 20-30% of budget to training.

What Global Manufacturing Leaders Expect from Warehouse Automation

Standardization Over Customization

Global manufacturers demand consistent processes across facilities—Thailand, Vietnam, China, Mexico. Automation must use standard configurations replicable elsewhere, not unique local solutions.

Granular Traceability for Risk Containment

When quality issues surface, complete material genealogy must be immediately available. Every automated transaction logs lot numbers, serial numbers, timestamps automatically without operator entry.

Stability, Uptime, and Predictability

Leaders prioritize reliable 95% daily throughput over systems hitting 100% occasionally but experiencing frequent breakdowns. Proven mature technologies with established maintenance protocols win over cutting-edge alternatives.

Multi-Language, Multi-Plant Visibility

Parent companies need real-time visibility across global facilities. WMS implementations support multiple languages for local operators while providing standardized dashboards in English or Japanese for headquarters review.

How to Start Warehouse Automation in Your Plant

The Right Way to Automate Your Warehouse

Start with process and data, not machines. Document flows, clean master data, and define measurable objectives. To automate warehousing successfully, plants must stabilize processes before introducing technology.

Pilot – Measure – Scale

Select focused pilot zones, implement automation, measure results, and scale only after stabilization. This phased approach is the safest way to automate warehousing while controlling risk and ROI.

Align HQ, Plant, and Operators Early

Engage headquarters: Involve parent company stakeholders from inception. Ensure alignment with corporate IT standards and strategic direction.

Include production teams: Warehouse exists to serve production. Production planners and line supervisors are internal customers defining requirements.

Involve warehouse operators: People executing daily tasks possess practical knowledge engineers miss. Their buy-in is essential for adoption.

Conclusion: Warehouse Automation as a Manufacturing Execution Strategy

Warehouse automation in manufacturing isn’t about impressive technology—it’s execution strategy building an operational foundation that converts production plans into reality consistently and accurately.

For Thai plants navigating labor constraints, regulatory requirements, and competitive pressures, this foundation enables operational stability independent of individual staff, data integrity supporting planning systems, process standardization satisfying global requirements, and traceability compliance meeting regulations without manual reconstruction.

The journey starts with commitment to process excellence and data discipline. Technology amplifies good processes; it cannot fix broken ones. Plants automating chaotic operations systematize chaos at higher cost. Plants building solid process foundations first, then adding automation strategically, create sustainable competitive advantages compounding over time.

For most manufacturing leaders, warehouse automation becomes less a technology discussion and more a question of execution capability.The question isn’t “What automation should we buy?” but “What operational capabilities do we need, and which technologies enable them most effectively?”

FAQs

Q: Is warehouse automation only for large, multinational plants?

A: No. The modular nature of modern automation (like AMRs and cloud-based WMS) has made it accessible and cost-effective for mid-sized plants. The key is to start with a focused, high-impact area.

Q: Do I need to replace my existing ERP system to automate?

A: Absolutely not. A best-in-class WMS is designed to integrate seamlessly with major ERP systems (like SAP, Oracle, or local solutions). The WMS manages real-time execution in the warehouse, while the ERP remains the system of record for financials and planning.

Q: What’s the first step, choosing a WMS or the automation equipment?

A: Always start with the WMS and process design. The software defines the operational logic and requirements. Choosing hardware first often leads to a suboptimal solution that cannot adapt to future needs.

Q: How long does it typically take to see a return on investment (ROI)?

A: For a well-scoped pilot project (e.g., automating raw material storage for a critical production line), many plants see a measurable ROI in 12-18 months through reduced errors, lower inventory, and fewer line stoppages. Full-facility projects have a longer but more substantial payback period.

Q: Can mid-sized plants implement automation in warehouse execution?

A: Yes. Modular solutions and phased approaches make automation in warehouse environments accessible beyond large multinational plants.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)