To solve the costly balancing act between stocking top-selling products and holding slow-moving inventory, focus on efficient inventory replenishment. That’s what you might have been told, but yet, do you know where to start?

If so, then let this comprehensive guide be your starting point. From discovering the 5 core replenishment methods to step-by-step calculation formulas, and understanding the strategy to turn reactive ordering into proactive multi location inventory management. Whether you’re managing a single location or coordinating stock across multiple sites, these proven strategies will help you maintain perfect product availability while maximizing cash flow and profitability. Let’s dive into it now.

What is Inventory Replenishment?

Inventory replenishment is the systematic process of restocking products to maintain optimal auto inventory levels that balance customer demand with operational efficiency. This strategic approach ensures businesses avoid stockouts while minimizing excess inventory carrying costs, particularly crucial for large enterprises managing complex supply chains across multiple markets.

For retail managers and purchasing decision-makers, understanding this process means recognizing that successful reorder inventory strategies directly impact both customer satisfaction and bottom-line profitability. The process involves calculating precise timing and quantities for restocking based on sales velocity, lead times, and market demand patterns.

3 Key Factors Governing Effective Replenishment

Effective inventory replenishment operates on several fundamental principles that drive supply chain success.

Lead time management ensures businesses’ reorder point calculations account for the duration between placing orders and receiving goods, enabling proactive restocking before inventory depletion occurs.

Demand forecasting forms another critical foundation, where accurate sales trend analysis enables precise prediction of when and how much stock requires replenishment. ShipBob’s research demonstrates that businesses using data-driven forecasting achieve 20-30% improvements in auto inventory levels optimization compared to traditional manual approaches.

Moreover, safety stock management acts as a buffer against unexpected demand spikes or supply disruptions, ensuring continuous product availability.

Modern inventory replenishment software automates these calculations and triggers, enabling seamless retail store replenishment processes that adapt to real-time market conditions across diverse operational environments.

What are the 5 Types of Inventory Replenishment?

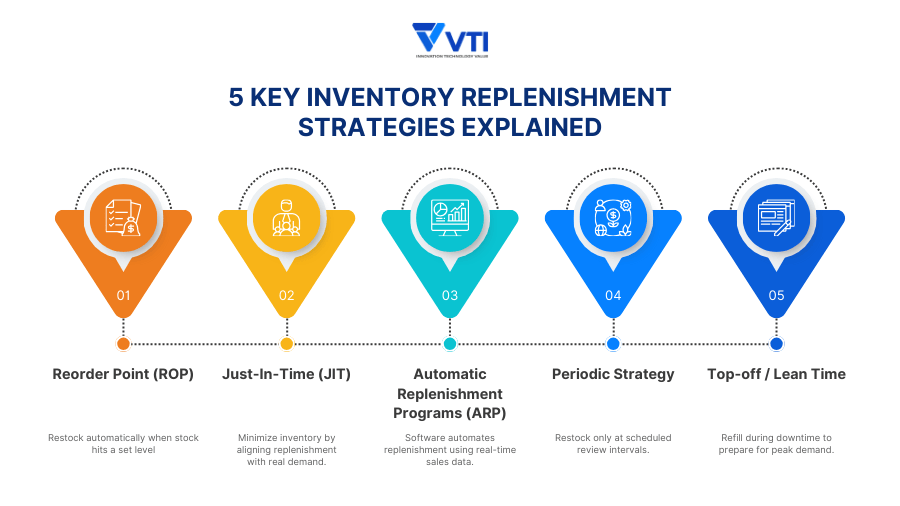

Reorder Point (ROP) Method

The reorder point method represents the most widely adopted inventory replenishment approach, where businesses establish predetermined inventory levels that trigger automatic restocking orders. This system calculates the optimal point to reorder inventory based on consumption rate, lead time, and safety stock requirements.

To illustrate, a retail electronics store might set a reorder point of 100 units for smartphones, meaning when stock drops to this level, the system automatically initiates a purchase order.

Just-In-Time (JIT) or Demand Strategy

Just-in-Time replenishment synchronizes retail store replenishment with actual customer demand, minimizing inventory holding costs by receiving goods precisely when needed.

However, this approach requires sophisticated demand forecasting and strong supplier relationships to ensure timely delivery without buffer stock. In other words, JIT implementation presents challenges, including vulnerability to supply chain disruptions and increased coordination complexity.

Therefore, companies in dynamic markets often combine JIT principles with strategic safety stock to balance efficiency with risk mitigation, particularly effective for multi location inventory management scenarios.

Automatic Replenishment Programs (ARP)

Automatic replenishment leverages inventory replenishment software to continuously monitor auto inventory levels and generate purchase orders without manual intervention. This technology-driven approach uses algorithms to analyze consumption patterns, seasonal trends, and supplier performance data for optimal store replenishment timing.

Modern ARP systems integrate real-time sales data with predictive analytics, enabling businesses to maintain optimal stock levels across multiple channels. This automation significantly reduces administrative overhead while improving retail stock replenishment accuracy, which is particularly valuable for large enterprises managing complex supply chains across diverse product categories.

Periodic strategy

With the periodic strategy, inventory is replenished at specific intervals. For example, you look at the levels every 3 months to see if they need replenishing. If the inventory levels are still fine, then you don’t reorder anything.

Even if your inventory runs out before that point, using a periodic strategy, you would not re-order until the cycle ends. Replenishment orders are placed only at the pre-determined review points.

Top-off/Lean time strategy

The top-off or lean time replenishment strategy takes advantage of low times to refill stock to acceptable levels. Think of it like refilling your car’s gas tank: instead of waiting for the low fuel light to come on, you top it off whenever you’re passing a gas station and have a few spare minutes. This ensures that popular products are always available to fulfill customer orders during peak times.

This strategy works well for businesses with high-demand SKUs with limited picking opportunities. It helps to improve efficiency when it minimizes the number of trips required for replenishment during peak periods, allowing businesses to focus solely on their primary task.

However, in practice, the top-off method is vulnerable to supply chain disruption. It’s dependent on vendor efficiency & flexibility, as well as whether you can predict the downtimes accurately.

How to Calculate Inventory Replenishment?

Calculating effective inventory replenishment begins with establishing precise reorder point (ROP) formulas that align with business demand patterns. The fundamental calculation combines average daily sales velocity, supplier lead time, and safety stock requirements to determine optimal inventory level thresholds.

The basic reorder point formula is:

| ROP = (Average Daily Usage × Lead Time) + Safety Stock. |

For example, if a retailer sells 50 units daily with a 10-day supplier lead time, the base calculation would be 500 units. Adding 20% safety stock brings the reorder point to 600 units, ensuring adequate coverage against demand fluctuations.

Modern inventory replenishment software automates these calculations while incorporating seasonal trends and promotional impacts. Inventory Planner’s analysis demonstrates that businesses using automated reorder point calculations achieve 25% better stock availability compared to manual methods.

What are the Benefits of Effective Inventory Replenishment?

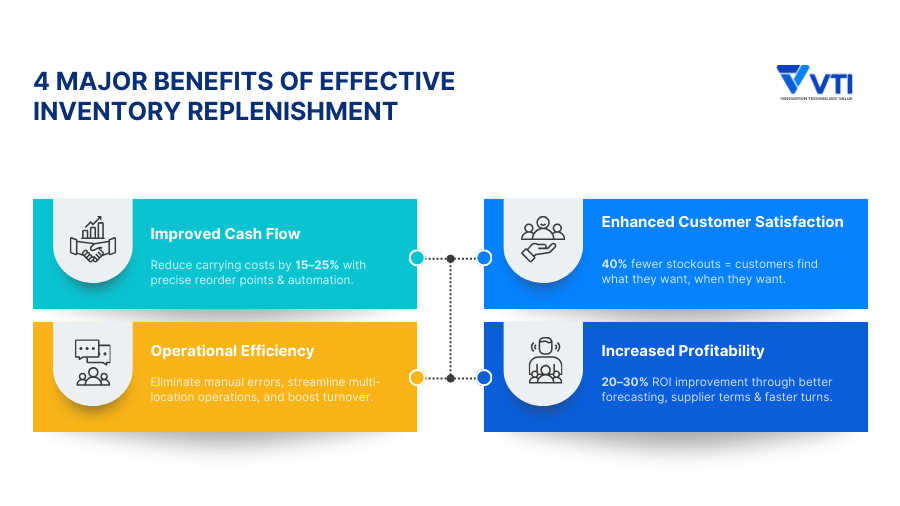

Improved Cash Flow

Effective inventory replenishment fundamentally transforms cash flow management by balancing working capital investment and operational needs. When businesses establish precise reorder point calculations and automate replenishment triggers, they eliminate costly overstocking while ensuring adequate product availability.

To illustrate, companies using data-driven replenishment strategies typically reduce inventory carrying costs by 15-25% while maintaining service levels above 95%. This improvement stems from eliminating emergency orders, reducing storage expenses, and minimizing obsolete inventory write-offs that drain profitability. Modern inventory replenishment software enables real-time inventory visibility into cash flow impact, allowing purchasing managers to optimize investment timing across product categories.

Enhanced Customer Satisfaction

Strategic retail store replenishment correlates with customer satisfaction by preventing stockouts, which is one of the main factors driving customers to competitors. According to research, by using an optimized replenishment system that can respond dynamically to demand fluctuations, businesses can achieve 40% fewer stockouts compared to manual inventory management approaches. With such automated inventory software, retailers can ensure customers find the desired products whenever they want. Moreover, reducing lost sales opportunities and supporting revenue growth initiatives across multiple channels.

Operational Efficiency: Streamlining Procurement and Sales Operations

Automated store replenishment systems eliminate manual ordering errors and reduce administrative overhead, enabling purchasing teams to focus on strategic supplier relationships rather than routine transactions. This efficiency gain becomes particularly valuable for multi location inventory management scenarios where coordinating replenishment across multiple sites traditionally requires significant resources.

Furthermore, integrated replenishment workflows synchronize procurement activities with sales forecasts, ensuring optimal timing for inventory arrivals. Retail stock replenishment automation reduces the time between identifying needs and receiving products, accelerating inventory turnover rates and supporting lean operational models that enhance competitive positioning.

Increased Profitability:

Optimized inventory replenishment generates sustained profitability improvements through multiple channels, including reduced carrying costs, improved supplier negotiation leverage, and enhanced demand forecasting accuracy. Cogsy’s analysis indicates that companies implementing comprehensive replenishment optimization achieve 20-30% improvement in inventory ROI within 18 months.

Additionally, predictable reorder inventory patterns enable better supplier relationship management, often resulting in volume discounts and improved payment terms. This strategic approach to inventory management creates competitive advantages through lower product costs, faster inventory turns, and improved cash conversion cycles that support long-term business growth objectives.

Best Practices for Effective Inventory Replenishment

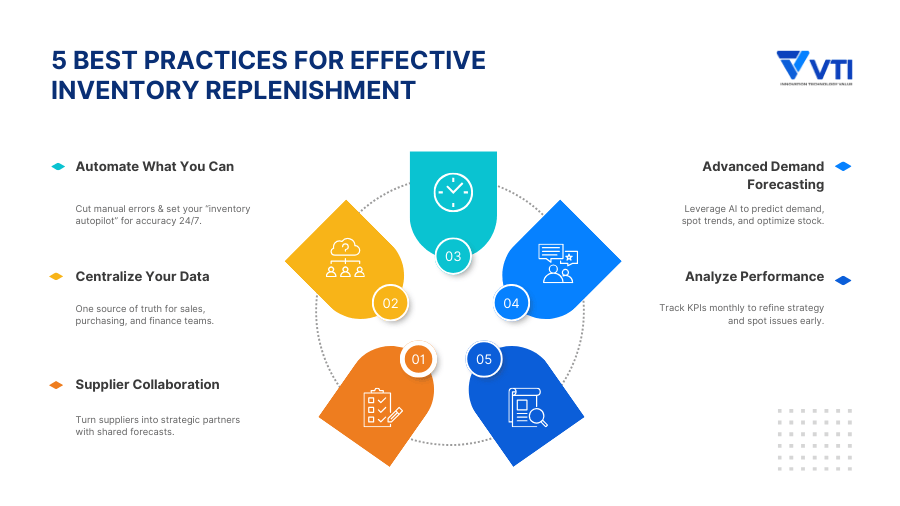

Automate What You Can

Think of automation as your inventory autopilot. While humans naturally make calculation errors during busy periods, automated systems work consistently around the clock, processing complex variables like seasonal trends and lead times to determine optimal reorder points.

Automation frees your team from error-prone manual calculations, allowing them to focus on strategic decisions like market analysis and supplier relationships. This shift from reactive firefighting to proactive planning often separates struggling businesses from thriving ones.

Centralize Your Data

Scattered inventory data across multiple systems is like navigating with conflicting street signs. Centralized data creates a single source where sales teams see real-time stock levels, purchasing accesses current forecasts, and finance tracks values.

This transparency eliminates the dangerous “telephone game” of information transfer, empowering every team member to make informed decisions quickly and confidently.

Supplier Collaboration

Transform suppliers from vendors into strategic partners. Share your growth plans, seasonal patterns, and challenges so they can proactively adjust production schedules to support your needs.

Collaborative suppliers become valuable sources of market intelligence, providing insights about emerging trends and potential disruptions. Regular business reviews and shared forecasts build relationships that prioritize your orders during supply shortages.

Advanced Technology for Demand Forecasting

Modern inventory systems are like crystal balls, using AI to predict demand patterns and optimize stock levels. These platforms analyze historical data, identify trends you might miss, and automatically adjust parameters as your business evolves.

Today’s technology integrates seamlessly across sales, purchasing, and accounting systems, creating connected ecosystems where accurate information flows freely between departments.

Analyze Performance

Regular performance analysis is like health checkups for your inventory system. Track key metrics like turnover rates, stockout frequency, and carrying costs to identify improvement opportunities.

Monthly reviews help spot trends early. Are certain products consistently overstocked? Do specific suppliers deliver late frequently?

Use these insights to continuously refine your strategy rather than relying on outdated approaches.

How to Choose the Right Inventory Replenishment Software?

Key Features to Look For

When evaluating inventory software, focus on these essential capabilities that separate robust solutions from basic tools:

- Integration Capabilities: Your chosen system should seamlessly connect with your existing e-commerce platforms, accounting software, sales channels, etc. Without proper integration, data silos between systems will surely hinder your automation process.

- Scalability: Can the software handle increased transaction volumes, additional product lines, and multiple warehouse locations as you grow? Consider both technical and pricing scalability. A system that works for 100 SKUs might struggle with 10,000.

- User-friendliness: The most feature-rich software becomes worthless if your staff avoids using it. Look for intuitive interfaces, logical navigation, and comprehensive training resources. Request demo sessions that mirror your actual workflows rather than generic presentations.

- Reporting and Analytics: Transform raw data into actionable insights. Essential reports include inventory turnover analysis, demand forecasting, supplier performance metrics, and profitability analysis by product. Advanced analytics should identify slow-moving inventory, predict stockouts, and recommend optimal reorder quantities.

- Pricing Models: Some charge per user, others by transaction volume or inventory value. Consider the total cost of ownership, including implementation fees, training costs, and ongoing support. Be wary of solutions with hidden charges for essential features or data exports.

- Customer Support: Evaluate response times, available support channels (phone, email, chat), and whether support is included or requires additional fees. Read user reviews specifically about support quality, as poor support can cripple your operations during critical moments.

Top 5 Leading Inventory Replenishment Solutions in Asia

The Asian market offers several outstanding vendors, each with distinct advantages for different business contexts:

VTI (Asia) stands out for its customized solutions with multi-location tracking and robust manufacturing capabilities. Depending on customers’ requirements and demands, VTI offers flexible deployment options. In other words, you can build your own scalable system without being locked in any particular vendor. VTI’s multilingual teams (English, Japanese, Chinese, and Korean) with flexible onshore/nearshore/offshore engagement models provide an outstanding support for enterprises across Asia.

Rakuten RMS (Japan) brings deep e-commerce integration, especially for businesses operating within Japan’s digital marketplace ecosystem. The system provides sophisticated demand forecasting using machine learning algorithms trained on Japanese consumer behavior patterns. However, its strength in local market integration may limit effectiveness for businesses operating primarily outside Japan. Pricing tends to be premium but includes comprehensive analytics and AI-driven insights.

SmartManager (Korea) focuses on lean inventory principles with real-time visibility across supply chains. The platform offers excellent mobile functionality and IoT integration capabilities, making it suitable for tech-forward operations. SmartManager’s Korean development team provides responsive support in multiple Asian languages, though their global integration options are more limited compared to Singapore-based competitors.

TradeGecko (Singapore) – now part of QuickBooks Commerce – combines inventory management with order management and accounting integration. The solution provides strong multi-currency support and regional tax compliance features essential for Asian cross-border trade. Their B2B wholesale focus makes them particularly suitable for distributors and wholesalers operating across Southeast Asian markets.

StockTrim (Singapore) specializes in inventory optimization using advanced algorithms to determine optimal stock levels. The platform integrates well with existing ERP systems and provides detailed analytics on inventory performance. Their focus on reducing excess inventory makes them attractive to businesses struggling with working capital optimization.

When comparing these solutions, consider your primary market focus, integration requirements with local platforms, and support for regional compliance needs. VTI’s comprehensive feature set and scalability make it suitable for diverse business models, while specialized solutions like Rakuten RMS or StockTrim excel in specific use cases or markets.

Final words

Effective inventory replenishment isn’t just about keeping shelves stocked; it’s about creating a strategic advantage that drives profitability, customer satisfaction, and operational efficiency simultaneously. By implementing the right replenishment method for your business, whether it’s reorder point systems, just-in-time approaches, or automated programs, you can reduce carrying costs by up to 25% while maintaining 95%+ product availability. The key lies in combining accurate demand forecasting with systematic calculation methods that turn inventory management from guesswork into science.

As supply chains become increasingly complex, businesses that master these replenishment fundamentals will outperform competitors through better cash flow, happier customers, and streamlined operations. Take time to evaluate your current replenishment processes and consider how these proven strategies could transform your inventory management from a cost center into a competitive weapon that supports sustainable business growth.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)