Think of it when our biggest customer places an urgent order on Friday afternoon, but your team can’t tell them when it’ll ship because nobody knows exactly what’s in stock or where it’s located. Sound familiar? This inventory blindness costs businesses millions in lost sales, excess inventory, and damaged customer relationships every year. Inventory visibility – the ability to track and monitor your products in real-time across your entire supply chain -has become essential for staying competitive in today’s fast-paced markets.

In this guide, you’ll discover what inventory visibility really means, why it’s crucial for your business success, and practical strategies to improve your tracking capabilities. You’ll also learn about common implementation challenges and emerging trends that will shape the future of inventory management.

What is Inventory Visibility?

Inventory visibility represents the real-time ability to track, monitor, and access comprehensive data on the status, quantity, and exact location of products throughout your entire supply chain. Think of it as having a bird’s-eye view of every item in your business ecosystem – from raw materials in your warehouse to finished products on retail shelves.

At its core, inventory visibility answers critical questions that keep business leaders awake at night: Where are my products right now? How much stock do I actually have? When will my next shipment arrive? For large enterprises operating across dynamic markets like Southeast Asia, these answers can make the difference between capitalizing on opportunities and losing customers to competitors.

Key Terminology

Data Source: The system from which inventory data originates. This could be a warehouse management system (WMS), an enterprise resource planning (ERP) system, a point-of-sale (POS) system, or an e-commerce platform.

SKU (Stock-Keeping Unit): A unique alphanumeric code used to identify and track a specific product and its variations (e.g., a T-shirt in a specific color and size).

Physical Measures: These are quantities that represent the status of your inventory. When a data source posts an inventory change, it uses a physical measure. Examples include:

- On-hand: The physical quantity of a product currently in stock.

- On order: The quantity that has been purchased from a supplier but not yet received.

- Sold: The quantity sold but not yet shipped.

- Quarantined: Inventory held for inspection or other reasons.

Calculated Measures: These are quantitative measures that are derived from a set of physical measures. They provide a more strategic view of inventory. A common example is Available-to-Promise (ATP), which calculates the quantity of a product that can be promised to a customer by factoring in both current on-hand stock and future supply. For instance, a simple “Total Available” calculated measure might be: On-hand + On order – Sold.

Why is Inventory Visibility Important?

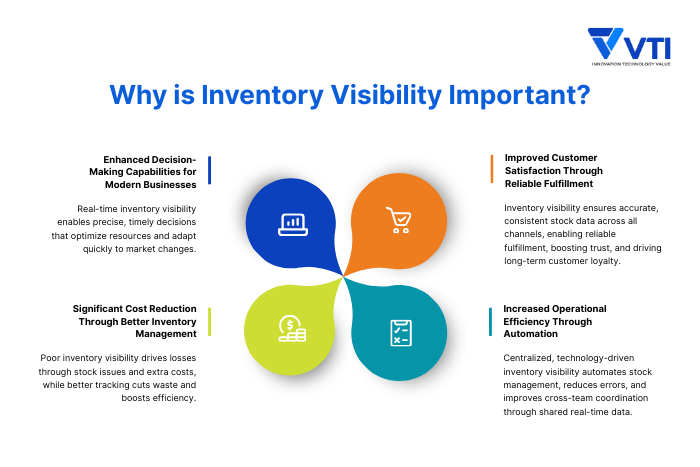

Enhanced Decision-Making Capabilities for Modern Businesses

Inventory visibility transforms business decisions by providing real-time data that eliminates guesswork from inventory management. When executives have comprehensive inventory insights, they make informed decisions about procurement, allocation, and demand planning – particularly valuable in dynamic Asia-Pacific markets where consumer preferences shift rapidly.

Enhanced visibility enables managers to identify trends early, spot bottlenecks before they impact operations, and allocate resources effectively across locations. For example, a retail chain can instantly redirect inventory from overstocked locations to high-demand stores, maximizing sales while minimizing excess costs.

Significant Cost Reduction Through Better Inventory Management

Poor inventory visibility devastates profitability through hidden costs, including lost sales from stockouts, damaged customer relationships, and overstock situations that tie up working capital. Research shows businesses with limited visibility carry 20-30% more safety stock than necessary, directly impacting cash flow.

Improved visibility reduces emergency procurement costs, minimizes obsolete inventory write-offs, and optimizes warehouse space. Accurate tracking eliminates expensive rush orders from poor planning and identifies slow-moving products before they become dead stock, enabling proactive markdown strategies that recover value rather than writing off entire product lines.

Improved Customer Satisfaction Through Reliable Fulfillment

Customer expectations demand accurate order fulfillment and transparent product availability communication. Inventory visibility enables businesses to provide real-time stock information across all sales channels, ensuring customers receive consistent, accurate availability and delivery information whether shopping online, in-store, or through B2B representatives.

This consistency proves crucial for omnichannel strategies in markets like Singapore and South Korea, where consumers move seamlessly between digital and physical touchpoints. Unified inventory visibility allows businesses to confidently promise delivery dates, offer alternatives when items are unavailable, and maintain customer trust, resulting in higher lifetime value and reduced churn rates.

Increased Operational Efficiency Through Automation

Centralized inventory systems with advanced visibility technologies streamline operations by automating routine tasks and eliminating error-prone manual processes. Automated reorder points, demand forecasting, and inventory allocation reduce administrative burden on purchasing teams while ensuring optimal stock levels, freeing human resources for strategic initiatives.

Improved visibility enhances coordination between departments and locations, reducing inefficiencies from miscommunication or outdated information. When warehouse teams, sales staff, and management work from the same real-time data, operations flow smoothly without the delays and conflicts that characterize businesses with fragmented inventory systems.

How Does Inventory Visibility Work?

Inventory visibility is achieved through a combination of key technologies and structured processes.

Core Technologies

These tools capture and manage the raw data of inventory movement:

Barcodes & QR Codes: The standard for item identification. Scanned at key points to track products moving through the supply chain.

Radio-Frequency Identification (RFID): Uses wireless tags for rapid, simultaneous scanning of multiple items without a direct line of sight, significantly speeding up counts.

Internet of Things (IoT) Sensors: Provide real-time data on not just location but also conditions like temperature and humidity, vital for sensitive goods.

Warehouse Management System (WMS): The software brain of the operation. It centralizes data from scanners and sensors to create a digital map of all inventory within a facility.

Essential Processes

To achieve true inventory visibility, businesses must implement robust processes that ensure the integrity and utility of the captured data. These processes can be broken down into three key stages:

Data Capture: The systematic scanning of items at every critical touchpoint – from receiving and putaway to picking and shipping – to ensure the foundational data is accurate.

Data Synchronization: The process of ensuring that all systems (e-commerce platform, physical stores, ERP) share a single, consistent, and up-to-date view of inventory levels. This prevents overselling and enables unified commerce.

Data Analysis: Using the collected data to optimize inventory. This involves analyzing sales trends to improve demand forecasting, automate replenishment, and identify slow-moving stock for clearance.

Challenges in Achieving Inventory Visibility

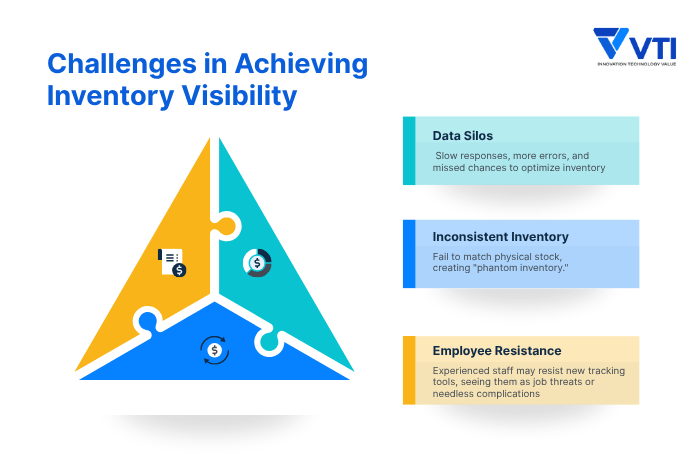

Data Silos That Fragment Business Intelligence

A key inventory visibility challenge is data silos, which are isolated systems that do not share information. Over time, large companies often develop these silos as different divisions use separate inventory management solutions. As a result, this creates a fragmented system where teams use incompatible data. Fragmentation is a major issue in the Asia-Pacific market, where regional teams often use different software for local reasons.

These silos then block a central inventory system. Consequently, decision-makers must manually gather data from many sources. This leads to slow responses, more errors, and missed chances to optimize inventory. Moreover, data silos prevent real-time inventory visibility because updates in one system do not automatically transfer to others, creating growing data errors.

Inconsistent Inventory Tracking Across Platforms

Another significant challenge is maintaining consistent tracking across platforms. Many businesses struggle with inconsistent inventory visibility supply chain operations because their ERPs, warehouse systems, and sales platforms use different formats and schedules. This, in turn, causes gaps in tracking where inventory movements are not shown correctly. System records then fail to match physical stock, creating “phantom inventory.”

Complexity even increases in Southeast Asia, where different countries have unique reporting rules. If inventory visibility software cannot integrate these requirements, maintaining accuracy becomes difficult. Additionally, legacy systems pose a problem. They often resist modern integration and standardization, which causes ongoing maintenance and data accuracy issues.

Employee Resistance to Technological Change

Perhaps the most underestimated challenge is employee resistance to new inventory visibility solutions. This is especially common when new systems change established workflows. For instance, experienced staff may resist new tracking tools, seeing them as job threats or needless complications.

This resistance can lead to poor data entry. Employees might also create workarounds or ignore new features. Therefore, the successful implementation of inventory visibility benefits needs good change management. Such a strategy should address concerns and clearly show the benefits. Training must also explain how improved visibility supports employees’ daily tasks and career growth. Finally, businesses should consider cultural factors, as teams in different markets may adopt technology differently, requiring tailored approaches.

How To Improve Inventory Visibility?

Integrating Technology for Real-Time Tracking

To improve visibility, businesses must first integrate advanced tracking technology. This provides accurate, real-time data across the entire supply chain. RFID (Radio Frequency Identification) technology offers one of the most powerful solutions, enabling automatic identification and tracking of items without direct line-of-sight scanning. Unlike traditional barcodes, RFID tags can be read at distances up to several meters and can track multiple items simultaneously, making them ideal for high-volume operations common in Southeast Asian distribution centers.

IoT sensors complement RFID systems by monitoring environmental conditions, movement patterns, and location data throughout the supply chain journey. These sensors provide continuous data streams that feed into centralized inventory systems, creating a comprehensive view of stock status from warehouse to customer delivery.

Establishing Standardized Processes for Monitoring

Standardization is the backbone of successful inventory visibility implementation, requiring consistent procedures everywhere. First, companies must create uniform data protocols. This ensures all team members follow the same process for handling inventory. This step is vital for multinational businesses because it prevents teams from creating conflicting methods.

Effective standardization also includes clear accountability and performance metrics that align with visibility goals. Furthermore, regular training helps staff learn new processes, while standard reports ensure consistent data interpretation. When all teams use the same protocols, the entire organization benefits from improved data accuracy and operational efficiency.

Conducting Regular Audits and Assessments

Regular audits act as a crucial quality control mechanism. They check the accuracy of inventory visibility software and identify areas for improvement. For instance, cycle counting helps maintain data integrity. In this process, different inventory sections are audited on a rotating schedule, which avoids disrupting daily work. These audits compare physical stock to system records. This comparison reveals issues like process failures, theft, or system malfunctions.

Moreover, full assessments should review the entire supply chain’s visibility. They check data flow, software integration, and automation effectiveness. Through this process, assessments find bottlenecks in information flow, allowing for targeted improvements. For large enterprises, quarterly assessments ensure inventory visibility solutions continue to meet evolving business needs.

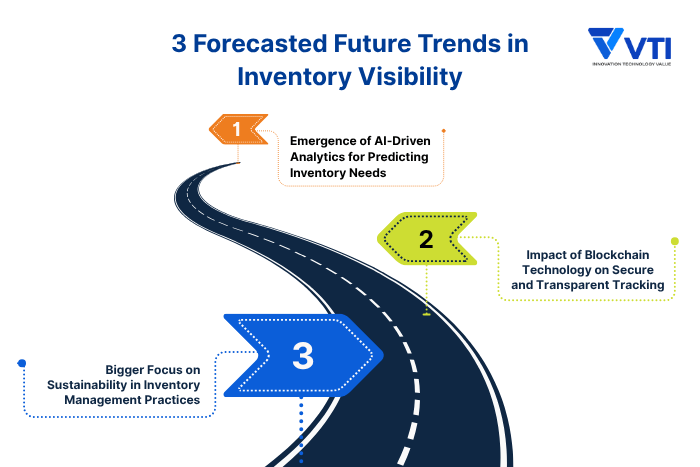

Future Trends in Inventory Visibility

Emergence of AI-Driven Analytics for Predicting Inventory Needs

Looking ahead, artificial intelligence (AI) will continue to change inventory visibility. It is already shifting management from reactive to proactive. Specifically, machine learning algorithms analyze large datasets, including sales history, trends, and economic forecasts. As a result, this leads to very accurate inventory predictions. Businesses can now use these predictive models to anticipate customer demand before it happens.

Modern AI solutions also use deep learning to find subtle patterns that humans might miss. Importantly, these systems constantly update their predictions using real-time market data to adapt to changes. In the diverse Asia-Pacific market, for example, AI analytics can handle regional variations while maintaining central control over global inventory

Impact of Blockchain Technology on Secure and Transparent Tracking

Blockchain is emerging as another force for inventory visibility in supply chain operations. It creates unchangeable records, which increases trust and transparency. Unlike traditional databases, blockchain provides permanent, tamper-proof records. This offers strong accountability for every transaction. Consequently, this technology is valuable for high-value or regulated goods where proving origin is critical.

Blockchain’s distributed nature also prevents single points of failure and provides real-time inventory visibility to all partners. Furthermore, smart contracts can automate tasks on the blockchain, such as triggering inventory updates, payments, and reports. This automation not only cuts administrative work but also ensures all partners have accurate, synced records. For international operations, blockchain offers standardized tracking that meets diverse compliance rules automatically.

Bigger Focus on Sustainability in Inventory Management Practices

Sustainability is also increasingly driving innovation in inventory visibility software. Businesses want to reduce their environmental impact while improving efficiency. Today, advanced systems track more than just location and quantity; they also monitor carbon footprint, packaging waste, and energy use. This expanded visibility helps companies make environmentally conscious choices about suppliers, routes, and warehouse sites.

Additionally, these inventory visibility software solutions help businesses eliminate waste throughout their supply chains. By tracking expiration dates and quality in real-time, they help manage perishable goods and support circular economy initiatives. Ultimately, companies can precisely measure their environmental performance, supporting both regulatory compliance and their corporate sustainability goals.

Final words

Inventory visibility isn’t just about knowing where your products are – it’s about transforming how your business operates. With real-time tracking and centralized data, you can make smarter decisions, reduce costs, and keep customers happy with reliable fulfillment. While implementing these systems comes with challenges like data silos and employee resistance, the benefits far outweigh the obstacles.

As AI, blockchain, and sustainability features continue to evolve, businesses that invest in inventory visibility now will be best positioned to capitalize on future innovations. The question isn’t whether you need better inventory visibility – it’s how quickly you can implement solutions that give you the competitive edge your business deserves.

Start by assessing your current gaps and taking the first steps toward complete supply chain transparency. At VTI, we offer a comprehensive and customized solution for businesses to gain efficient inventory visibility, leading to reduced costs and improved customer experience.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)