Businesses with 95% or higher inventory accuracy experience 30% fewer stockouts and a 25% improvement in order fulfillment rates. While businesses with low inventory accuracy lose millions in lost sales, expedited shipping fees, and damaged customer relationships every year. Inventory accuracy – the alignment between your digital records and physical stock – directly impacts your bottom line and competitive position.

In this comprehensive guide, you’ll discover exactly what inventory accuracy means, why it’s critical for large-scale operations, and proven methods to calculate and improve it. Whether you’re managing multiple warehouses or complex supply chains, understanding these fundamentals will help you reduce costs, enhance customer satisfaction, and gain operational advantages that drive sustainable growth in today’s demanding marketplace.

What is inventory accuracy?

Inventory accuracy measures how closely your recorded inventory data aligns with your actual physical stock. In essence, it’s a key performance indicator (KPI) that reflects the reliability of your inventory records.

For any business dealing with physical products, maintaining a high level of inventory accuracy is paramount for efficient operations and sustained profitability. Inventory discrepancies between what your system says you have and what’s actually on your shelves can lead to a cascade of costly problems like stockouts, overselling, or inefficient resource allocation.

Achieving near-perfect inventory accuracy, often targeted at 95% or higher, is a continuous and vital process for any business that manages stock. Moreover, achieving high inventory accuracy helps prevent phantom inventory – situations where systems display available stock that doesn’t actually exist.

How to check inventory accuracy?

The primary measurement for inventory accuracy utilizes a straightforward calculation:

Inventory Accuracy = (Counted Units ÷ Units on Record) × 100. |

This percentage reveals how well your recorded inventory matches physical counts during cycle counts or comprehensive audits.

Advanced organizations implement multiple accuracy metrics, including location accuracy, which verifies items are stored in correct positions, and condition accuracy, ensuring product quality matches system records. Regular inventory reconciliation processes using these metrics enable continuous monitoring and improvement of data integrity.

Furthermore, modern inventory audit software automates accuracy tracking through real-time monitoring and exception reporting. These technological solutions help identify patterns in inventory shrinkage and negative inventory situations, enabling proactive corrections before discrepancies impact business operations.

For businesses across Asia, VTI's Inventory Management System provides customizable dashboard tracking and seamless ERP integration to optimize inventory accuracy.Inventory Optimization Through IMS Dashboards

What is a good inventory accuracy rate?

The answer isn’t the same for every business – it depends on the industry you’re in.

In retail and e-commerce, where shelves need to be stocked and customers expect next-day delivery, the leaders typically achieve 98-99% accuracy. That means almost every item recorded in their systems is exactly what’s sitting in the warehouse. But the reality for many retailers is very different – some still struggle to keep accuracy above 80%, which leads to stockouts, missed sales, and frustrated customers.

Manufacturers face their own challenges. With raw materials, work-in-progress items, and finished goods moving through complex supply chains, even reaching 97% accuracy is considered strong. Yet industry averages hover closer to 75%, leaving plenty of room for error and improvement.

And then there’s healthcare and pharmaceuticals, where the stakes couldn’t be higher. A misplaced unit isn’t just a cost problem; it can be a compliance violation or even a safety risk. For that reason, inventory accuracy in this field must be almost flawless, at 99.5% or above.

No matter the sector, the rule of thumb is clear: 95% should be your baseline. Anything below puts you at risk of stock discrepancies and unhappy customers. Every percentage point above that, however, moves you closer to world-class performance – helping you cut costs, reduce stockouts, and build trust with the people who rely on your products.

Why Inventory Accuracy Matters?

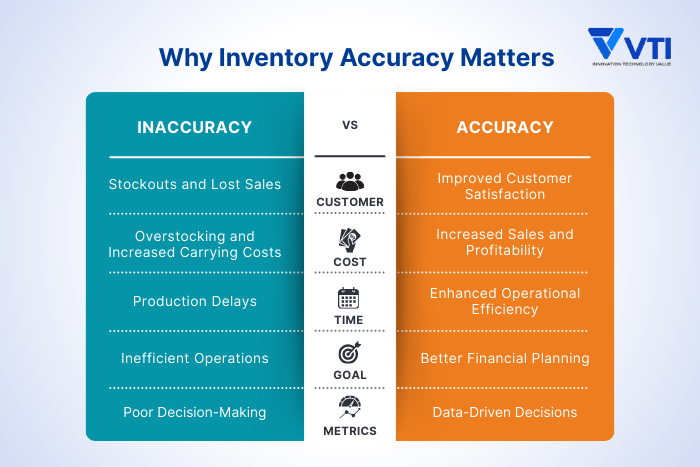

The High Cost of Inaccuracy

Stockouts and Lost Sales: When systems indicate items as available but they’re actually out of stock, businesses face immediate revenue loss and long-term damage to their customer relationships. These phantom inventory situations create frustration and disappointment, leading to decreased loyalty, negative word of mouth, and permanent market share loss.

Overstocking and Increased Carrying Costs: Inventory inaccuracy that understates stock levels forces businesses to maintain excessive inventory. Carrying costs extend beyond purchase prices to include warehousing, insurance, taxes, and obsolescence risks. These costs typically range from 20-30% of inventory value annually, eroding profit margins and restricting business flexibility.

Production Delays: Inaccurate raw material records can trigger catastrophic production disruptions. When planning relies on incorrect data, manufacturers discover shortages only when production begins, forcing costly shutdowns and expedited procurement.

Inefficient Operations: Inventory inaccuracies force warehouse staff to spend hours searching for misplaced items or conducting impromptu counts, reducing throughput and increasing handling costs.

Poor Decision-Making: Inaccurate data undermines purchasing decisions, promotional planning, and financial projections. Sales teams develop promotions for unavailable products, while demand forecasting models produce unreliable predictions that create procurement strategies resulting in shortages or excess stock.

The Advantages of Accuracy

Improved Customer Satisfaction: Accurate inventory enables consistent delivery promises and prevents overselling situations. Research shows that businesses maintaining 98% accuracy achieve 35% higher customer retention rates than those below 85% accuracy.

Increased Sales and Profitability: Precise management maximizes revenue while minimizing expenses. Preventing stockouts captures otherwise lost sales, while accurate tracking identifies shrinkage early and eliminates costly emergency procurement that costs 15-25% more than planned purchases.

Enhanced Operational Efficiency: Accurate data enables smooth workflows where pickers trust location information, reducing search time. Strategic replenishment becomes possible when teams rely on accurate consumption patterns.

Better Financial Planning: Reliable inventory valuation supports accurate financial statements and cash flow planning. Budget development becomes more precise based on reliable turnover rates and carrying costs.

Data-Driven Decisions: Accurate information empowers sophisticated purchasing strategies, better pricing decisions, and targeted marketing campaigns based on reliable product availability data.

What Causes Inventory Inaccuracy?

Inventory accuracy is the backbone of successful business operations, yet many companies struggle with persistent inventory discrepancies that can devastate their bottom line. When your records don’t match your physical stock, you’re dealing with more than just numbers on a spreadsheet – you’re facing potential stockouts, disappointed customers, and significant financial losses. Understanding the root causes of these discrepancies is the first step toward building a more reliable inventory management system.

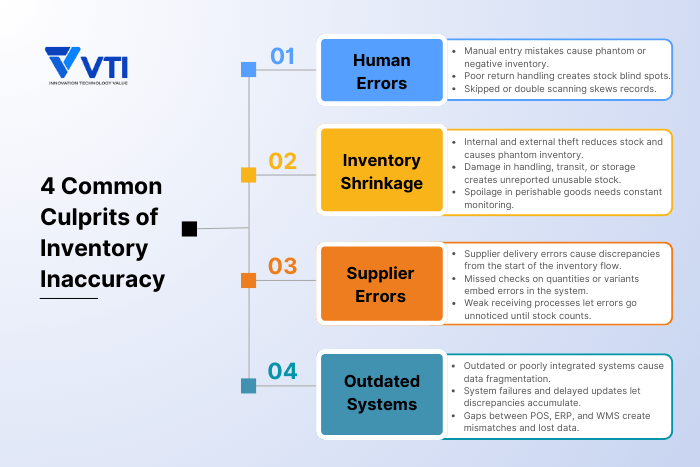

Human Error

Manual data entry errors, including mistyped quantities or SKUs, can create substantial distortions in inventory records that cascade through your entire system. These seemingly small mistakes often result in phantom inventory – where your system shows stock that doesn’t actually exist – or negative inventory situations where physical stock exceeds recorded quantities.

The impact of human error extends beyond simple miscounts. Inadequate handling of returns frequently creates inventory blind spots, where returned items aren’t properly scanned back into the system, leading to artificial stock deficits. Similarly, skipped or double scanning during transactions can make your inventory appear higher or lower than reality.

Inventory Shrinkage

Internal theft by employees and external theft by customers or organized retail crime directly reduce physical stock while often going undetected in inventory management systems. This creates a dangerous scenario where businesses continue to sell products they don’t have, leading to phantom inventory situations.

Beyond theft, damage during handling, transit, or storage creates unusable products that frequently go unreported, skewing inventory data and causing unexpected stockouts. Without proper tracking and timely updates, inventory shrinkage can significantly impact your inventory accuracy and make effective inventory reconciliation nearly impossible.

Supplier Errors

Inaccurate deliveries from suppliers introduce inventory discrepancies at the very beginning of your inventory flow, making downstream inventory accuracy nearly impossible to maintain. When receiving staff fail to catch incorrect quantities or wrong product variants, these errors become embedded in your system, creating persistent data inconsistencies.

The lack of rigorous receiving processes increases the risk that supplier errors go unnoticed until physical counts reveal significant mismatches. This delayed detection makes inventory reconciliation more challenging and can result in weeks or months of inaccurate data.

Outdated Inventory Systems

Inefficient technology represents a major barrier to maintaining inventory accuracy in today’s fast-paced business environment. Outdated or poorly integrated inventory management systems create data fragmentation between sales, warehouse, and procurement modules, making comprehensive inventory reconciliation a complex puzzle. When systems lack barcode scanning, RFID, or automated picking technologies, they rely heavily on manual data entry, significantly elevating the risk of human error and subsequent inventory discrepancies.

System failures, crashes, or a lack of automated updates can delay reconciliation processes and allow discrepancies to accumulate unchecked. Gaps between point-of-sale systems, enterprise resource planning platforms, and warehouse management systems often cause transaction mismatches and lost data logs.

How do you ensure the accuracy of inventory counts??

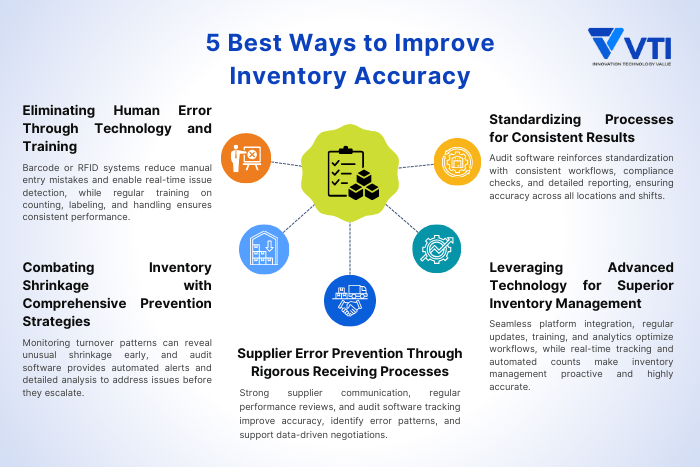

Eliminating Human Error Through Technology and Training

The most effective approach to reducing human error combines advanced scanning technology with comprehensive employee training. Implementing barcode or RFID scanning technologies significantly reduces manual data entry errors that frequently cause inventory discrepancies. These automated systems not only improve inventory accuracy but also provide real-time data that enables immediate detection of problems like phantom inventory situations.

Regular employee training on accurate counting, labeling, and inventory handling procedures creates a foundation for consistent performance. Establishing double-check or peer review systems for critical inventory tasks like receiving and shipping adds a layer of protection against errors. Inventory audit software can support these efforts by tracking employee performance and identifying areas where additional training may be needed. Routine cycle counts, supported by modern auditing tools, help catch discrepancies early and reduce the burden of full physical inventories while maintaining superior inventory accuracy.

Combating Inventory Shrinkage with Comprehensive Prevention Strategies

Addressing inventory shrinkage requires a multi-layered approach that combines physical security with process improvements. Enhanced security measures, including surveillance cameras and controlled access areas, serve as the first line of defense against theft.

Implementing strict damage reporting protocols helps track non-theft-related inventory shrinkage. Quality checks further improve the detection of these losses. Monitoring inventory turnover patterns can quickly reveal unusual losses. Inventory audit software strengthens this process. It provides automated alerts when shrinkage exceeds normal limits. The system also enables detailed analysis of shrinkage patterns.

Supplier Error Prevention Through Rigorous Receiving Processes

Preventing supplier errors requires instituting rigorous receiving processes that include detailed inspections against purchase orders. Training staff to promptly report and rectify discrepancies with suppliers creates accountability throughout the supply chain. Modern receiving scanners automatically match deliveries to orders, significantly reducing the risk of inventory discrepancies at the point of entry and preventing downstream phantom inventory or negative inventory situations.

Maintaining good supplier communication and conducting regular performance reviews helps minimize delivery mistakes over time. Inventory audit software can track supplier performance metrics, identify patterns in delivery errors, and provide data-driven insights for supplier negotiations. This proactive approach to supplier management significantly improves overall inventory accuracy and reduces the time spent on inventory reconciliation.

Standardizing Processes for Consistent Results

Documenting and communicating clear Standard Operating Procedures (SOPs) for all inventory activities eliminates the variability that leads to inventory discrepancies. Thorough training of all relevant staff on these procedures, combined with periodic reviews and updates, ensures processes remain effective as operations evolve. Quality control checkpoints and audits enforce adherence to processes and maintain high standards of inventory accuracy.

Inventory audit software plays a crucial role in standardization by providing consistent workflows, automated compliance checks, and detailed reporting on process adherence. This technology ensures that standardized procedures are followed consistently across all locations and shifts, reducing the human variability that can compromise inventory accuracy.

Leveraging Advanced Technology for Superior Inventory Management

Upgrading to integrated inventory systems with real-time tracking is a highly impactful improvement for businesses. Modern audit software integrates barcode scanners, RFID, and automated picking systems into a single comprehensive solution. This integration virtually eliminates phantom inventory and negative inventory situations.

Linking sales, procurement, warehouse, and accounting systems ensures consistent data across all platforms. This makes inventory reconciliation simple instead of time-consuming. Regular system updates and continuous user training maximize technology investment returns. Data analytics features identify error patterns and improve workflow efficiency.

Advanced audit software offers real-time visibility into inventory shrinkage. It supports automated cycle counting schedules and generates detailed reports. These features turn inventory management from a reactive process into a proactive discipline. By combining technology with improved processes and training, businesses achieve superior inventory accuracy. This accuracy is essential for success in today’s competitive marketplace.

VTI's Inventory Management System (IMS) offers a comprehensive solution for businesses to efficiently track, control, and optimize their inventory in real-time, leading to reduced costs and improved overall supply chain efficiency through automation and insightful analytics.

View moreFinal words

Achieving high inventory accuracy isn’t just about better record-keeping – it’s about building a foundation for operational excellence that directly impacts your profitability and customer relationships. When your digital inventory records align with physical reality, you eliminate costly surprises, reduce emergency expenses, and enable confident decision-making across your entire organization.

Start by assessing your current accuracy levels, then implement the technological and process improvements that best fit your operation. Remember, every percentage point improvement in inventory accuracy translates to reduced costs, happier customers, and stronger competitive positioning. At VTI, we offer a comprehensive and customized solution for businesses to gain efficient inventory accuracy, leading to reduced costs and improved customer experience.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)