One of the biggest challenges for all manufacturing businesses is maintaining the standard of their products’ quality over time. Some defect classification methods have been applied to improve the quality of each batch. However, many manufacturers or the QA team still cling to manual methods, leading to time-consuming, labor-intensive, and highly error-prone.

With the adoption of artificial intelligence (AI), we can make the workflow become more efficient and reduce human error significantly. In this case study about disk classification, we will explore how computer vision and machine learning can leverage the traditional defect inspection system for manufacturers to a whole new level.

Overview of inspection system

An inspection system refers to a system that is designed to detect defects, errors, or deviations from specific criteria in a product or process. The goal of an inspection system is to ensure that products or processes meet certain quality standards and to identify any issues that may arise in real time.

When integrating advanced machine learning algorithms, the inspection system can analyze images of products and detect flaws or abnormalities with much higher accuracy and at an impressive rate, compared to traditional or human inspectors. Manufacturing companies not only can optimize their costs for human resources but also save expenses for rectifying batches with defective products.

Description

VTI’s client wanted to reduce product costs and improve the quality of the current inspection system. They required an AI-powered disk quality classification system, built on cloud-based platform with:

- High-precision AI detector

- Cause-of-failure investigation by AI estimation

The main challenge is to be able to adopt new technologies and migrate into cloud, while maintaining the operations of the existing system. This can be considered an initial project for a long-term strategy towards a smart factory.

Some additional information about the core technologies of the inspection system:

- Application: C#, Python

- Platform: GCP, Sci-kit Learn SDK

- OS: Windows

Results

The inspection system for the disk manufacturer came out with significant features, including:

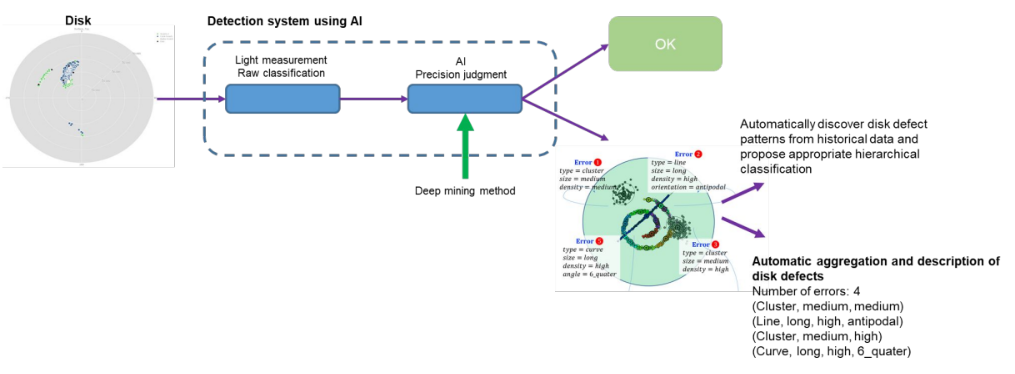

- Automated disk classification (automatic clustering), including 2-step detection system: raw classification, and AI precision judgment using deep mining method. The AI precision judgment can automatically discover disk defect patterns, based on historical data, and automatically describe the disk defects.

- Cloud on-premises executed on both sides

- High performance: The system can handle up to 1.2 million cases on a daily basis, demonstrating its exceptional processing power and ability to manage and analyze large datasets.

- High precision: The classification process can carry out results with the accuracy of 90%

Output demo

Why choose VTI to apply AI to defect inspection system for manufacturing?

VTI Group is the leading technology and IT service provider based in Vietnam, Japan, Korea, and Singapore. We provide one-stop AI solutions for business growth to all-scale companies in a wide variety of industries such as manufacturing, construction, retail, transportation, and internet services, and support customers’ business growth through the digital transformation business.

VTI’s AI development service empowers businesses with cost-effective and automated solutions. With the thorough industry know-how and a broad range of AI technologies, specifically specialized in computer vision, natural language processing, and data mining, we are confident to maximize customer technology ROI. Our end-to-end AI service covers everything business managers are looking for:

- Building smart workflows

- Running data analytics

- Automating manual operations

- Developing smart demand forecast systems, etc.

If you have any questions about the AI-powered inspection system for manufacturing, do not hesitate to contact us for more details.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)