30% to 40% of warehouse stock in many businesses remains unmoved for over 90 days. Those idle items are silently tying up thousands of dollars in working capital and taking up square meters of valuable storage space. This is a reality for many businesses, yet most leaders lack a clear way to spot and manage slow-moving inventory before it turns into a costly liability. That’s where the inventory aging report comes in – a data-driven tool that categorizes stock based on how long it has been sitting in your warehouse.

This comprehensive guide will explain what inventory aging reports are, how to calculate and generate them, why they’re critical for your business’s health, and which software solutions can automate the process. You’ll discover proven strategies for managing aged inventory, improving cash flow, and making data-driven purchasing decisions that optimize your operations.

What Is An Inventory Aging Report?

An inventory aging report is a financial and operational tool that categorizes your stock based on how long items have remained in inventory, providing clear visibility into which products are moving and which are tying up valuable capital. This report breaks down inventory into specific periods – typically 0-30 days, 31-60 days, 61-90 days, and 90+ days – enabling managers to identify slow-moving inventory that requires immediate attention quickly.

Moreover, this report serves as a critical decision-making instrument for purchasing teams and executives, helping them understand which products generate strong turnover versus those creating cash flow challenges. For large businesses operating across diverse markets, these insights prove invaluable for optimizing procurement strategies and reducing excess stock that can burden operations.

Key Metrics Used in Inventory Aging Reports

The aged inventory report typically includes essential metrics such as SKU identification, on-hand quantities, unit costs, total values, and calculated days in inventory. These data points work together to provide a comprehensive view of inventory health, enabling managers to assess both individual product performance and overall inventory aging management effectiveness.

Additionally, understanding your inventory valuation method – whether FIFO (First In, First Out) or LIFO (Last In, First Out) – remains crucial for accurate cost calculations, though it doesn’t alter the fundamental aging analysis that drives operational decisions.

Consequently, these metrics enable businesses to calculate key performance indicators like inventory turnover rates and identify products requiring immediate clearance strategies to free up working capital and warehouse space.

Why Is Inventory Aging Important For A Business?

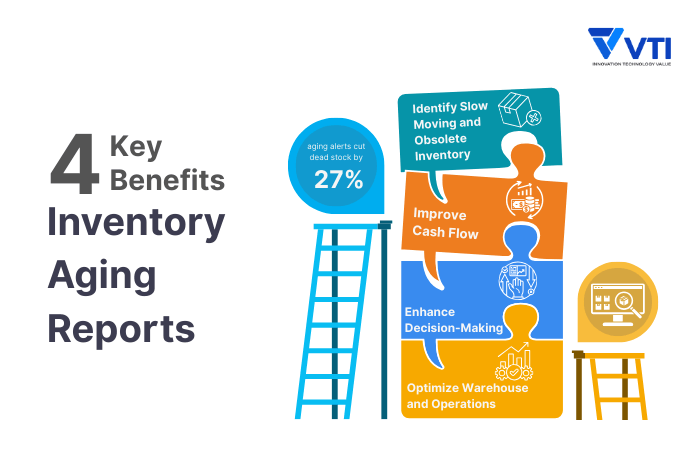

Identify Slow-Moving and Obsolete Inventory

The biggest benefit of an inventory aging report is its ability to reveal which products are not selling as expected. It serves as an early warning system, flagging items that have been in stock for too long.

This helps businesses identify dead stock that may never sell, pinpoint slow movers tying up capital and warehouse space, and prevent future losses by avoiding reorders of poorly performing items.

Improve Cash Flow

Every unsold product represents money tied up on the shelf. An inventory aging report shows where capital is locked.

By selling old stock, even at a discount, businesses can free up working capital and reinvest it in more profitable areas. This also helps reduce carrying costs – storage, insurance, and management – that silently erode profits over time.

Enhance Decision-Making

Inventory aging data supports stronger business strategies. It provides clear insights into how products are performing in the market.

Companies can use it to optimize pricing through markdowns or bundles, adjust purchasing and production to better match demand, and improve demand forecasting using historical aging trends.

Optimize Warehouse and Operations

Aged inventory directly affects warehouse efficiency. Items that sit too long occupy space that could be used for faster-moving, more profitable goods.

The report also supports better stock rotation. For perishable or time-sensitive items, it helps enforce FIFO or FEFO practices, reducing waste and spoilage.

Cutting 6x costs, boosting 50% efficiency, Japanese leading retailer optimized inventory imports via a procurement management system with VTI![]()

How Do You Calculate Inventory Aging?

Calculating inventory aging begins with determining the number of days each item has remained in your warehouse since its arrival date. The basic formula involves subtracting the item’s receipt date from the current date, giving you the exact days in inventory for each SKU.

Inventory Value per Bucket=∑(Quantity on Hand×Unit Cost) |

Most inventory aging management systems automate this calculation, but understanding the underlying process helps ensure accurate reporting.

Organizing your data requires collecting essential information, including SKU numbers, quantities on hand, unit costs, receipt dates, and current inventory values. Systematic data collection forms the foundation for reliable aged inventory report generation across all product categories.

Additionally, categorizing items into aging buckets (0-30 days, 31-60 days, 61-90 days, and 90+ days) provides the strategic framework needed to identify slow-moving inventory and prioritize management actions accordingly.

Methods for Calculating Aging Using Various Metrics

The most common calculation method employs the FIFO approach, where the oldest inventory is given priority in age calculations. This method assumes that older stock should move first, making it particularly relevant for businesses managing perishable goods or seasonal merchandise that faces obsolescence risks.

Some organizations prefer LIFO calculations for specific accounting purposes, though this approach may not reflect actual physical inventory movement patterns. The choice between methods affects your inventory aging report calculations and should align with your overall inventory valuation strategy.

Consequently, modern inventory management systems often provide both calculation options, enabling businesses to generate reports that match their financial reporting requirements while maintaining operational visibility into excess stock patterns.

What Are The Best Practices For Managing Aged Inventory?

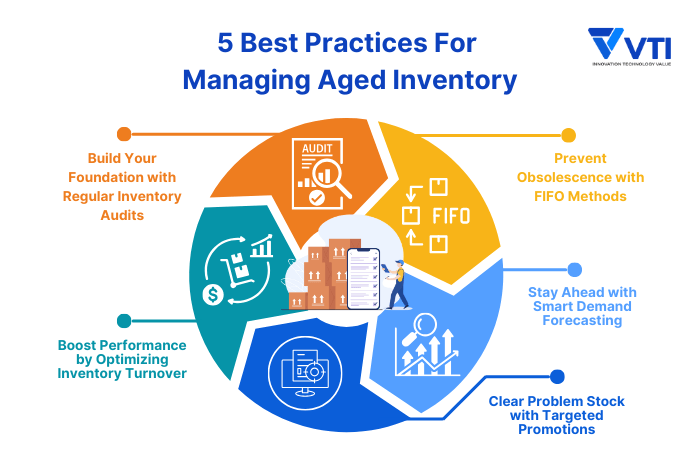

Build Your Foundation with Regular Inventory Audits

Effective inventory aging management starts with accurate data. Regular audits are the backbone of reliable inventory aging reports. They give you real-time visibility into stock status. Physical counts and cycle counting help you spot slow-moving inventory early. This proactive approach lets you address aged inventory before it becomes a problem. You can make decisions while products still have value. Consistent audits prevent excess stock from tying up your capital. They create a solid foundation for all your inventory planning decisions.

Boost Performance by Optimizing Inventory Turnover

Smart inventory turnover directly impacts your profits. Strong inventory aging management depends on analyzing your sales data carefully. Identify which products create slow-moving inventory challenges. Streamline your product lines by cutting underperformers. This improves your inventory aging reports and reduces aged inventory buildup.

Focus your resources on high-demand items that sell consistently. Better turnover strategies lead to improved cash flow. They also minimize excess stock levels across your operation.

Prevent Obsolescence with FIFO Methods

FIFO methodology prevents inventory from becoming outdated. This approach to inventory aging management keeps aged inventory moving systematically. It stops excess stock from accumulating over time.

Your inventory aging reports become more actionable with FIFO principles. The method shows you exactly which products need immediate attention. FIFO is especially important for perishable or time-sensitive goods. It prevents waste and keeps customers satisfied. This discipline extends beyond managing slow-moving inventory into total quality control.

Stay Ahead with Smart Demand Forecasting

Advanced forecasting transforms inventory aging management from reactive to proactive. Modern inventory aging reports work best with trend analysis and market intelligence. Use historical sales data and forecasting tools together. This helps you anticipate demand changes and adjust purchasing decisions. You’ll significantly reduce slow-moving inventory risks.

Smart forecasting prevents the costly cycle that creates aged inventory problems. It helps you avoid excess stock accumulation while maintaining service levels.

Clear Problem Stock with Targeted Promotions

Strategic promotions solve slow-moving inventory issues immediately. Good inventory aging management includes creative marketing for aged inventory. Turn problem stock into opportunities through smart sales tactics. Your inventory aging reports can identify products perfect for discounts or bundles.

These campaigns clear excess stock while generating revenue. They also introduce customers to new products. Balance promotional pricing with profit margins carefully. Use these campaigns to learn and improve future purchasing decisions.

Which Software Can Generate Inventory Aging Reports?

| Criteria | VTI | SAP | Oracle NetSuite | Microsoft Dynamics 365 | Finale Inventory |

Key Features | Real-time inventory tracking, advanced forecasting, supplier management, automated stock replenishment, cloud-based (AWS), end-to-end omnichannel fulfillment | ERP integration, stock tracking, barcode scanning, automated reorder points, demand forecasting, lot/serial tracking, reporting | Real-time 360° inventory visibility across warehouses, order management, POS integration, demand forecasting, cycle counting, replenishment automation | Comprehensive real-time stock management, quality control, automated goods receipt, order fulfillment, vendor-managed inventory, batch/lot/serial tracking, AI-driven forecasting | Multichannel ecommerce inventory sync, lot/serial tracking, multi-location support, dynamic reorder points, automated order fulfillment, extensive packing and reporting |

Integration Options | ERP, Warehouse Management Systems (WMS), POS, CRM, e-commerce platforms | Extensive integration within the SAP ERP ecosystem; supports third-party system integration | Native integration with Oracle applications; APIs enable third-party integrations | Deep integration within Microsoft ecosystem | Connects with Shopify, Amazon, eBay, QuickBooks, ShipStation, multiple marketplaces, and POS systems |

APAC Regional Support | Strong local presence and support teams; multilingual support including English, Korean, and Japanese; proven experience with Japanese and broader APAC markets | Significant presence with local partners in Singapore, Japan, and other hubs in Asia | Regional data centers and implementation partners across APAC support local compliance | Supports operations in APAC with localization capabilities; partners and consultants in the region | Primarily English-language support; expanding reach in Asia with integrations tailored for e-commerce businesses in APAC |

Weaknesses | Less recognized as a global brand compared to SAP/Oracle | High cost and complexity; overwhelm mid-sized businesses | Steep learning curve; premium pricing | Pricing and complexity may be high for small businesses | Limited advanced features; mainly English support |

Best for | Mid-to-large enterprises, retail, distribution, and logistics firms in APAC | Large global enterprises with complex supply chains and financial integration | Retailers, manufacturers, distributors needing a flexible cloud ERP | Broad industries (retail, manufacturing, wholesale) with strong compliance and quality control | e-commerce SMEs, especially multichannel sellers |

Final words

Managing inventory aging effectively can transform your business operations from reactive firefighting to strategic planning. By implementing regular inventory aging reports, you gain the visibility needed to identify slow-moving stock before it becomes obsolete, optimize your cash flow, and make smarter purchasing decisions. The key lies in choosing the right tools and establishing consistent monitoring processes that flag aging inventory at critical thresholds.

Ready to streamline your inventory and transform your business? Contact VTI today to discover how our inventory management solutions can help you achieve more effective operations and higher profits.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)