Have you ever discovered that you’re sitting on a thousand-dollar worth of slow-moving inventory while running out of your best-selling products? A few years ago, this scenario played out daily across businesses due to reliance on outdated spreadsheets and manual tracking methods. However, it is different now. The modern inventory management system offers a solution that transforms this chaos into streamlined operations.

And to give you an overview of this modern system, this comprehensive guide goes through what inventory management systems are, their key benefits, the different types available, and best practices for successful implementation. Importantly, you’ll also discover leading vendors serving the Asia-Pacific market. Whether you’re managing multiple locations across Southeast Asia or planning digital transformation initiatives, understanding these is crucial for maintaining a competitive advantage in today’s fast-paced business environment.

What is an Inventory Management System?

An inventory management system (IMS) is a comprehensive technological solution that enables businesses to track, monitor, and control their stock levels across multiple locations and channels. It processes information from various touchpoints to provide real-time visibility into what you have, where it’s located, and when you need to replenish supplies. This serves as a digital command center that automates the complex task of traditional inventory tracking.

Let’s show you a peek at this advanced system.

For example, modern IMS platforms use barcode scanning, RFID technology, and automated data collection to maintain accurate, up-to-date inventory records, rather than relying on manual counts or spreadsheets. This real-time monitoring provides instant visibility into stock levels, enabling businesses to respond quickly to demand fluctuations.

Or, inventory forecasting capabilities analyze historical data and market trends to predict future inventory needs.

Or, an automated procurement management system generates orders whenever stock reaches predetermined points.

This automation reduces manual errors and ensures a consistent supply flow, preventing stockouts and costly overstock situations. The IMS is, therefore, particularly valuable for large businesses operating across Asia, where supply chain complexity and regional distribution networks demand precise inventory control.

Check out VTI’s case study about Cloud Procurement System: A Retail Chain’s Cloud Procurement System with 6x Lower Cost

What are the Benefits of Implementing an Inventory Management System?

Before IMS | After IMS | |

| Inventory Accuracy | Manual errors common | 99%+, automated & barcode-based |

| Stockouts | Frequent due to poor visibility | Rare with real-time tracking |

| Carrying Costs | High from excess safety stock | Lower via demand forecasting |

| Fulfillment Speed | Slow, manual reordering | Fast, automated procurement |

| Stock Visibility | Periodic snapshots only | Continuous, real-time |

| Decision-Making | Reactive, incomplete data | Proactive, analytics-driven |

Cost Reduction Through Improved Inventory Accuracy

Implementing an inventory management system delivers significant cost savings by eliminating the expensive mistakes that plague manual inventory control. When businesses rely on spreadsheets or paper-based tracking, inventory counting errors can result in stockouts, which disappoint customers, or overstocking, which “exploits” valuable working capital.

The financial impact becomes even more pronounced for cross-border retailers and manufacturers. Consider a retail chain with warehouses in different locations/countries, without unified inventory management. If each location maintains excess safety stock to avoid stockouts, the carrying costs across the network are hence multiplied.

Modern inventory management platforms can maintain accuracy rates over 99%, dramatically reducing these costly errors.

Enhanced Visibility and Control Over Stock Levels

Real-time inventory monitoring transforms how decision-makers understand and manage their stock positions. Traditional inventory control methods provide only periodic snapshots, leaving uncertainty about current stock levels between counting cycles. However, now, perpetual inventory systems can continuously track every movement, purchase, and sale, providing instant visibility into stock status across all locations and channels.

This proves especially valuable for businesses operating in fast-moving markets like South Korea and Japan, where consumer demand can shift rapidly.

Moreover, warehouse inventory management systems equipped with mobile capabilities allow managers to access critical stock information from anywhere, enabling quick responses to supply chain disruptions or unexpected demand spikes.

Streamlined Procurement Processes Leading to Faster Fulfillment

As mentioned earlier, automated reordering capabilities within modern inventory management systems eliminate the manual processes that slow down procurement cycles. When stock reaches the preset level, the system automatically generates purchase orders, reducing the time between need identification and order placement.

Moreover, the advanced inventory forecasting features further optimize procurement by analyzing historical sales data, seasonal trends, and market patterns to predict future needs. This predictive capability helps purchasing teams secure better supplier terms, especially in the case of omnichannel fulfillment, through more accurate quantity commitments, while reducing rush order costs that occur whenever stock runs unexpectedly low.

Data-Driven Decision Making Through Analytics and Reporting

Finally, IMS’s comprehensive reporting capabilities transform raw inventory data into actionable business insights. Sales and inventory management systems generate detailed analytics showing which products move fastest, identify slow-moving stock that ties up capital, and reveal seasonal patterns that inform future purchasing decisions.

Advanced inventory systems also provide ABC analysis functionality, categorizing products by revenue contribution, which helps focus attention on the most profitable items.

Additionally, turnover ratios and carrying cost analyses enable CFOs to optimize working capital allocation and improve overall financial performance.

These insights are valuable for DX managers, CXOs,… implementing digital transformation initiatives across their organizations.

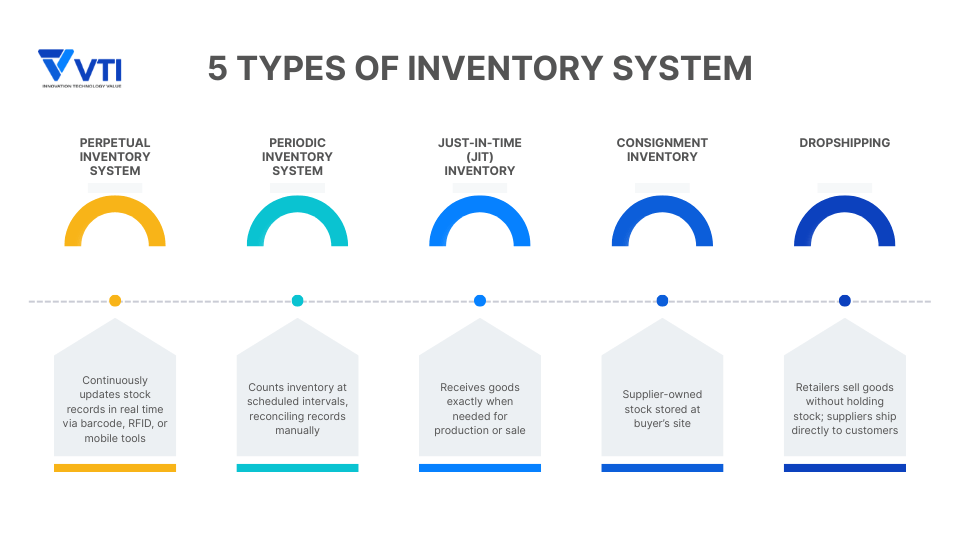

What are the 5 main types of inventory management systems?

Perpetual Inventory System

A perpetual inventory system continuously monitors stock movements in real-time, updating inventory records and central databases immediately when items are received, sold, or transferred. This inventory management platform uses barcode scanning, RFID technology, or mobile inventory management systems to capture transactions instantly, providing managers with up-to-the-minute stock visibility. Unlike traditional methods that rely on periodic checks, perpetual systems maintain accurate inventory counts throughout the day.

Periodic Inventory System

Periodic inventory systems conduct physical inventory counts at predetermined intervals – typically monthly, quarterly, or annually-rather than tracking movements continuously. During these scheduled periods, staff manually count all items and reconcile physical quantities with recorded amounts. This approach suits businesses with stable, predictable inventory flows or those managing lower-value items where real-time precision isn’t critical.

While less technologically intensive than perpetual systems, periodic inventory control requires significant labor investment during counting periods. Many businesses in Southeast Asia use hybrid approaches, combining periodic physical counts with perpetual tracking for high-value items to balance accuracy with operational efficiency.

Just-in-Time (JIT) Inventory

Just-in-time inventory management focuses on receiving goods precisely when needed for production or sale, minimizing storage costs and reducing waste from obsolete stock. This lean approach requires sophisticated inventory forecasting capabilities and reliable supplier relationships to ensure materials arrive exactly when required without disrupting operations.

JIT systems are particularly effective in manufacturing environments where predictable production schedules enable precise material planning, or in F&B inventory management, where food loss is always a headache.

However, implementing JIT requires robust supplier networks and contingency planning, factors especially important for businesses operating across diverse markets, where supply chain reliability can vary significantly.

Consignment Inventory

Consignment inventory is a supply chain arrangement where a supplier retains ownership of goods stored at a customer’s location until the items are actually used or sold. This allows businesses to access inventory without upfront investment while suppliers maintain control over their products until the point of consumption, plus a broader market reach and better shelf placement.

This arrangement particularly benefits both parties when testing new products or entering new markets.

Here is how it works, briefly. The modern inventory software automatically keeps track of which products you, retailers, don’t own yet (consignment items). The payment to the supplier only occurs when those items are sold. At the same time, it shows you how much consignment stock you have left – all without you having to manually calculate payments or track what belongs to whom.

Yet, it requires such sophisticated inventory control systems capable of managing multiple ownership structures within a single warehouse or retail location that few internal IT teams can handle.

Dropshipping

Dropshipping represents the ultimate in inventory outsourcing, where retailers sell products they never physically handle. When customers place orders, retailers forward purchase details to suppliers who ship directly to end customers. This model eliminates warehouse inventory management requirements and reduces capital investment, making it attractive for businesses testing new markets or product lines.

However, dropshipping requires robust unified inventory management systems to coordinate between multiple suppliers, track order status, and manage customer communications. Success depends heavily on supplier reliability and integrated technology platforms that provide visibility across the entire fulfillment process.

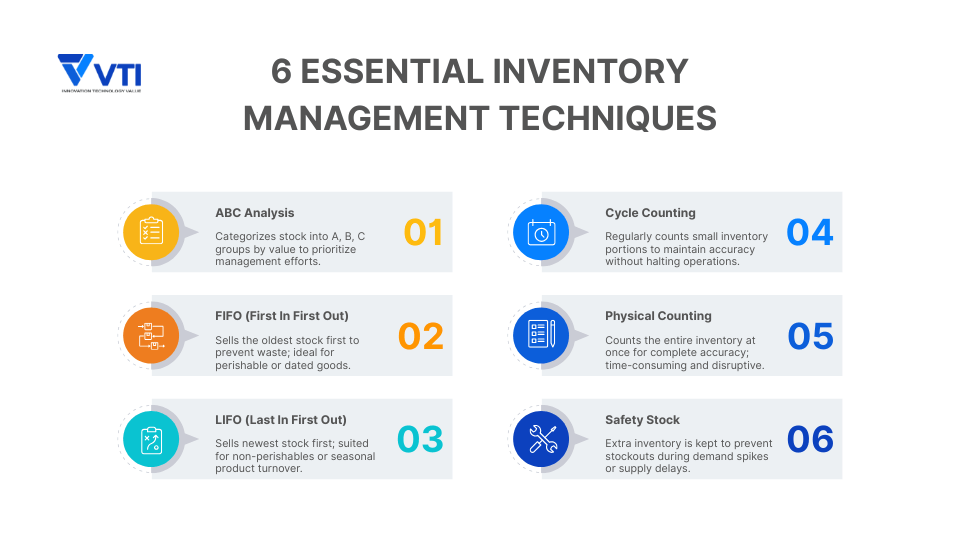

Essential Inventory Management Techniques

Smart inventory management goes far beyond simply counting products on shelves. To control your system efficiently, it require strategic thinking, data-driven decisions, and the right techniques to balance supply with demand while minimizing costs and maximizing efficiency. And here are typical methods to fully “utilize” the powerful system you have.

ABC Analysis: Prioritizing Your Stock

Think of ABC analysis as your inventory’s VIP system. This technique categorizes your products into three distinct groups based on their value and impact on your business. Category A items are your high-value products that generate the most revenue but typically represent only 10-20% of your inventory. Category B items fall into the middle ground with moderate value and volume, while Category C items are low-value products that make up the bulk of your inventory count.

Consider how a clothing store might implement this system. Their Category A items could include designer jackets and premium denim that drive significant profits despite limited quantities. Category B might encompass mid-range sweaters and casual wear, while Category C would include accessories like belts, socks, and basic t-shirts.

By focusing more attention and resources on managing Category A items, the store ensures its most profitable products never run out while maintaining adequate stock levels for other categories.

FIFO vs. LIFO: Managing Stock Rotation

Stock rotation strategies can make or break your inventory efficiency, especially when dealing with products that have expiration dates or seasonal relevance. First-In, First-Out (FIFO) operates like a grocery store’s dairy section, where older products get sold first to prevent spoilage and waste. This method proves invaluable for perishable goods, cosmetics, and any items with shelf lives.

Conversely, Last-In, First-Out (LIFO) works well for non-perishable items where newer stock gets prioritized. This approach often makes sense for seasonal merchandise or fashion items where the latest arrivals should be featured prominently.

Cycle Counting vs. Physical Counting

You could either choose to shut down operations for comprehensive inventory counts (physical counting) or cycle count a smaller portion in a determined period.

The former provides complete snapshots of your entire inventory (what you actually have), yet, disruptive and time-consuming.

Meanwhile, the latter involves regularly counting small portions of your inventory throughout a certain period (month, year,…), spreading the workload, and maintaining ongoing accuracy.

Here’s a simple example:

If you like physical counting, you might want to close your bookstore for a weekend and have your team count every single book, magazine, and item in the entire store.

Or instead, you might count just the fiction section on Monday, cookbooks on Tuesday, children’s books on Wednesday, and so on – rotating through different sections each day so you eventually count everything without ever shutting down your store.

Cycle counting keeps your finger on the pulse of inventory accuracy without operational interruptions, though it requires consistent scheduling and a systematic approach to be effective.

Safety Stock

Safety stock comes into play as your insurance policy against uncertainty. Maintaining strategic buffer inventory helps prevent stockouts during unexpected demand spikes or supplier delays, particularly crucial in volatile markets where customer expectations remain high.

Mastering these inventory management techniques creates a foundation for sustainable business growth. By combining this with other methods such as ABC analysis for prioritization, cycling counting, or JIT, you’ll transform your inventory from an operational headache into a competitive advantage.

In summary, there is no one-size-fits-all option. But, you should start by evaluating which technique addresses your most pressing inventory challenge, then gradually integrate others to build a comprehensive management system that drives both efficiency and profitability.

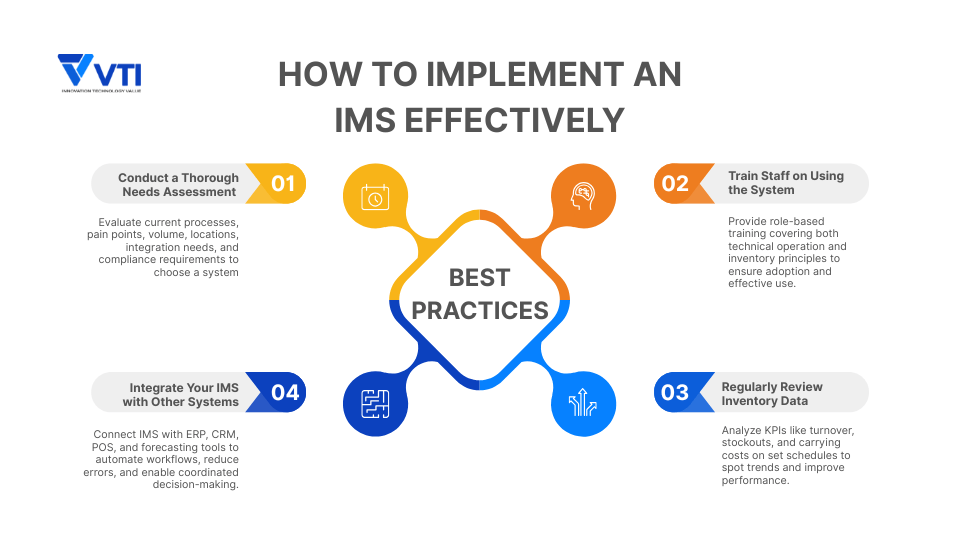

Best Practices for Implementing an Inventory Management System Effectively

Conduct a Thorough Needs Assessment Before Selecting an IMS

A successful inventory management system implementation begins with a comprehensive evaluation of your current operations and future requirements. This assessment should analyze your existing inventory processes, identify pain points, and establish clear performance metrics for improvement. Consider factors such as inventory volume, number of locations, integration requirements with existing systems, and specific industry regulations that affect your business.

For large enterprises operating across diverse markets, this evaluation becomes particularly crucial. Different regions may have varying compliance requirements, supplier networks, and customer expectations that influence system selection. Document your current inventory challenges, whether they involve stockout frequency, carrying cost optimization, or warehouse inventory management inefficiencies, to ensure the chosen solution addresses your most pressing operational needs.

Train Staff Adequately on Using the System to Maximize Benefits

Even the most sophisticated inventory management platform fails without proper user adoption and competency. Develop a comprehensive training program that covers both technical system operation and underlying inventory management principles. Staff should understand not just how to input data or generate reports, but why accurate inventory monitoring matters for business success.

Implement role-based training that addresses different user needs. Warehouse staff require expertise in barcode scanning and physical inventory procedures, while managers need proficiency in inventory forecasting and analytics interpretation. According to IBM, organizations that invest in thorough training see significantly higher ROI from their inventory system implementations.

Regularly Review Inventory Data for Trends and Performance

Once your inventory control system is operational, establish routine data analysis practices to identify trends, anomalies, and improvement opportunities. Regular review cycles should examine key performance indicators such as inventory turnover rates, stockout frequencies, and carrying costs across different product categories and locations.

Develop standardized reporting schedules that provide actionable insights for different stakeholders. Weekly reports might focus on immediate operational concerns like stock levels and reorder requirements, while monthly analyses can reveal seasonal patterns and supplier performance trends. This systematic approach to inventory stock management enables proactive decision-making rather than reactive problem-solving, particularly valuable for businesses managing complex supply chains across multiple countries.

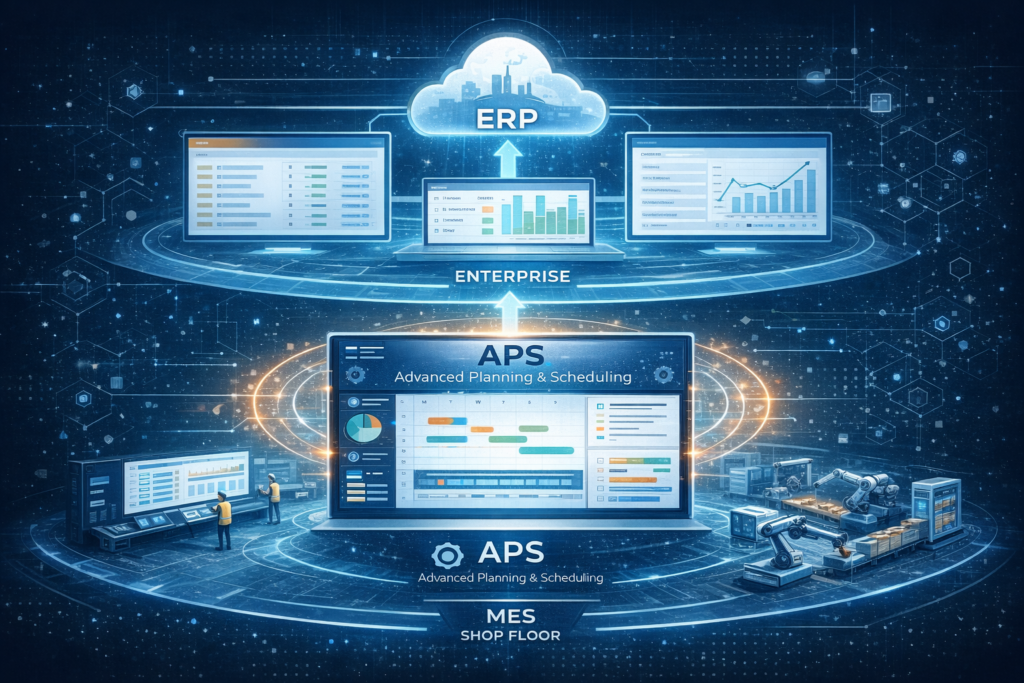

Integrate Your IMS with Other Systems to Create Synergy Across Departments

Maximizing the value of your inventory management system requires seamless integration with complementary business applications. Connect your IMS with enterprise resource planning (ERP) systems, customer relationship management (CRM) platforms, and sales and inventory management systems to create automated workflows that eliminate manual data entry and reduce errors.

Integration enables powerful capabilities such as automatic purchase order generation when stock reaches reorder points, real-time inventory updates during sales transactions recorded in your POS, and coordinated demand planning between sales forecasts and inventory procurement.

For businesses operating unified inventory management across multiple locations, this connectivity ensures consistent data flow and coordinated decision-making.

In a nutshell, integrated systems provide the data foundation necessary for advanced analytics and digital transformation initiatives, which precisely navigate your business through the unpredictable retail future.

Top Vendors in Asia for Inventory Management Solutions

Selecting the right inventory management system vendor requires careful evaluation of features, scalability, integration capabilities, and regional support. For large businesses operating across Asia and beyond, choosing a vendor with proven expertise in the regional markets ensures better implementation success and ongoing support.

The following analysis examines leading inventory management solution providers that serve enterprise clients in these dynamic markets, focusing on their unique strengths, scalability options, and local market presence.

VTI: Comprehensive Analytics with Customizable Features

VTI offers a comprehensive inventory management system designed specifically for large enterprises requiring real-time inventory tracking and advanced analytics. Their platform provides customizable features that adapt to various business models, from retail chains to manufacturing operations.

VTI’s strength lies in its ability to scale across multiple locations while maintaining unified inventory management capabilities. Integration capabilities include seamless connectivity with ERP systems, warehouse management systems, e-commerce platforms, POS systems, CRM, and so on.

VTI maintains strong local support across Asia, with dedicated teams providing implementation assistance and ongoing technical support 24/7 with fluent communication in English, Korean, and Japanese.

Moreover, their robust platform meets the highest security standards with ISO/IEC 27001:2022 certification, ensuring enterprise-grade data protection and compliance.

SAP: Enterprise-Level Inventory Solutions

SAP provides enterprise-grade inventory control systems built for large-scale operations across multiple countries and currencies. Their inventory management module integrates deeply with its well-known ERP ecosystems, providing a comprehensive automated business process from financial, procurement, to production systems.

In Asia, SAP maintains a significant local presence across markets, with implementation partners and support centers in major business hubs like Singapore and Japan.

Therefore, its solution excels in handling complex supply chains and regulatory compliance requirements common in diverse Asia-Pacific markets.

Despite these strengths, weaknesses typically involve high implementation costs and complexity that may overwhelm mid-market businesses.

Oracle: Flexible Cloud-Based Inventory Management

Oracle’s inventory management platform delivers cloud-based solutions that scale from regional operations to global enterprises.

Its strength lies in providing flexible deployment options, from on-premise installations to fully cloud-hosted solutions. In addition, notable capabilities include native connectivity with Oracle’s broader business application suite, plus APIs for third-party system integration. According to Oracle, its platform is efficient in supporting complex multi-location inventory scenarios of large retailers and manufacturers.

Its local support includes regional data centers and implementation partners across Asia-Pacific markets.

However, the weaknesses are still steep learning curves and premium pricing structures.

Zoho Inventory: Accessible Solution for Growing Businesses

Zoho Inventory provides an accessible inventory management platform that bridges the gap between simple inventory tracking and enterprise-level functionality.

Their system offers core inventory control features with straightforward implementation and user-friendly interfaces. Zoho’s strength lies in providing essential inventory management capabilities without overwhelming complexity, as well as a more reasonable price.

Zoho is supporting businesses from startups to SMEs, with upgrade paths as requirements grow, including integrating with popular accounting systems, e-commerce platforms, and so on.

Yet, its weaknesses include limited advanced features and reduced functionality for complex multinational operations.

Vendor Comparison Table

| Criteria | VTI | SAP | Oracle | Zoho Inventory |

| Key Strengths | Real-time inventory tracking & advanced analytics; highly customizable for various business models; enterprise-grade security (ISO/IEC 27001:2022) | Deep ERP integration; handles complex supply chains & compliance; strong automation across financial, procurement, and production | Flexible cloud/on-premise deployment; strong multi-location inventory support; native integration with Oracle suite | User-friendly & easy implementation; affordable entry-level pricing; upgrade paths for growing businesses |

| Scalability & Deployment | Scales across multiple locations; suitable for large enterprises | Designed for large-scale, multi-country, multi-currency operations | Scales from regional to global operations | Suitable for startups to SMEs; limited for complex multinationals |

| Integration Capabilities | ERP, WMS, POS, CRM, e-commerce, and more | Native to SAP ERP ecosystem; extensive third-party integration options | Oracle ecosystem + APIs for third-party systems | Integrates with accounting software, e-commerce platforms, etc. |

| Local Market Presence in Asia | Strong local support teams in Asia; 24/7 multilingual support (English, Korean, Japanese) | Large presence in Asia (Singapore, Japan, etc.); strong partner network | Regional data centers & partners across APAC | Strong in Singapore & developed markets; expanding in emerging ones |

| Weaknesses | Less global brand recognition compared to SAP/Oracle | High implementation cost; complexity may overwhelm SMEs | Steep learning curve; premium pricing | Limited advanced features; less suited for enterprise-scale operations |

Final words

Implementing the right inventory management system isn’t just about tracking stock—it’s about transforming your entire operational foundation. The benefits are clear: reduced costs through improved accuracy, enhanced visibility for better decision-making, streamlined procurement processes, and data-driven insights that drive growth.

Whether you choose a perpetual system for real-time tracking or explore options like JIT for cost minimization, success depends on thorough needs assessment, comprehensive staff training, and seamless integration with existing systems.

As businesses across Asia continue embracing digital transformation, those with robust inventory management systems will be better positioned to respond to market changes, satisfy customer demands, and optimize working capital. Take time to evaluate your current processes, consider the most suitable vendors and approaches outlined here, and begin planning your inventory management transformation journey.

![[FREE EBOOK] Strategic Vietnam IT Outsourcing: Optimizing Cost and Workforce Efficiency](https://vti.com.vn/wp-content/uploads/2023/08/cover-mockup_ebook-it-outsourcing-20230331111004-ynxdn-1.png)